Nuclear Laboratories

EPRI’s laboratories are at the forefront of research into topics that are important to the nuclear industry. The Charlotte laboratory boasts world-class facilities and capabilities for evaluating components and materials and researching new inspection, fabrication, and repair techniques in non-destructive evaluation (NDE), welding and fabrication, metallurgical characterization, and chemistry and corrosion.

In the laboratory environment, EPRI can replicate field welding conditions to test and demonstrate techniques, materials, process, and equipment. Staff working on nuclear-related projects are certified for all major NDE techniques including radiography testing, ultrasonic testing, magnetic particle testing, visual testing, eddy current testing, and ASME codes and standards.

Nondestructive Evaluation Laboratory

Nondestructive evaluation technology enables users to identify potentially hidden problems long before those problems can damage equipment, impact safety, or affect plant operations. In its 30 years of NDE operations, EPRI has developed world-class expertise in the application of NDE technology to nuclear plant systems and in the training of personnel to support NDE applications.

Our NDE Laboratory develops, evaluates, and demonstrates a number of leading-edge technologies:

Advanced Ultrasonics Laboratory

Contact: Mark Dennis, Program Manager, mdennis@epri.com

The NDE program’s advanced ultrasonics laboratory has historically housed state-of-the-art transducers, instruments, computers, and software to support existing examination challenges and to research innovative solutions for future issues. Additionally, new technologies such as advanced Ultrasonic Testing methods, artificial intelligence, and NDE Modeling and Simulation techniques are being investigated to improve the NDE inspection process. The goal of the advanced ultrasonics laboratory is to provide technology that will provide more accurate, comprehensive, and reliable NDE within the inspection process.

OnScale

- Cloud engineering simulation platform with a multiphysics solver that can be used to model and simulate ultrasonic testing in NDE. Allows users to run massive numbers of ultrasonic testing simulations in parallel for more realistic results

Optison

- Visualization of ultrasonic wave propagation for enhanced training

Sonatest Wheel Probe

- Efficient corrosion mapping using ultrasonic phased array technology used by NDE and Plant Engineering

Verasonics Vantage Ultrasonic Instrument

- Laboratory/research grade ultrasonic phased array instrument with arbitrary wave generation capabilities and open platform

- The Phased Array Company Pioneer Ultrasonic Instrument

- Commercial grade ultrasonic phased array instrument with full-matrix capture, plane wave imaging, and arbitrary wave generation capabilities

Zetec TOPAZ Ultrasonic Instruments

- Portable ultrasonic phased array instrument in 32 and 64 channel configurations

- The 64 channel instruments are capable of acquiring full-matrix capture data and displaying total focusing method images in real time

Eddy Current Technology (NDE)

Contact: Nathan Driessen, Technical Leader II, ndriessen@epri.com

Eddy current technology enables inspection of critical power plant components, including heat exchangers, fuel pool liners, and reactor materials susceptible to selective leaching. The NDE lab demonstrates the viability of eddy current technology for these and other nuclear-specific applications. For example, to address concerns regarding the reliability of eddy current inspections for heat exchangers, our air-transportable mockups can be deployed to the field so you can test your inspectors.

Guided Wave Technology

Contact: Mike Quarry, Principal Technical Leader, mquarry@epri.com

Ultrasonic guided wave technology provides greater coverage in a much shorter time and allows the examination of inaccessible components such as fuel assemblies and buried pipe. Once a potential problem area has been identified, inspectors can then focus on it with a more detailed examination technique.

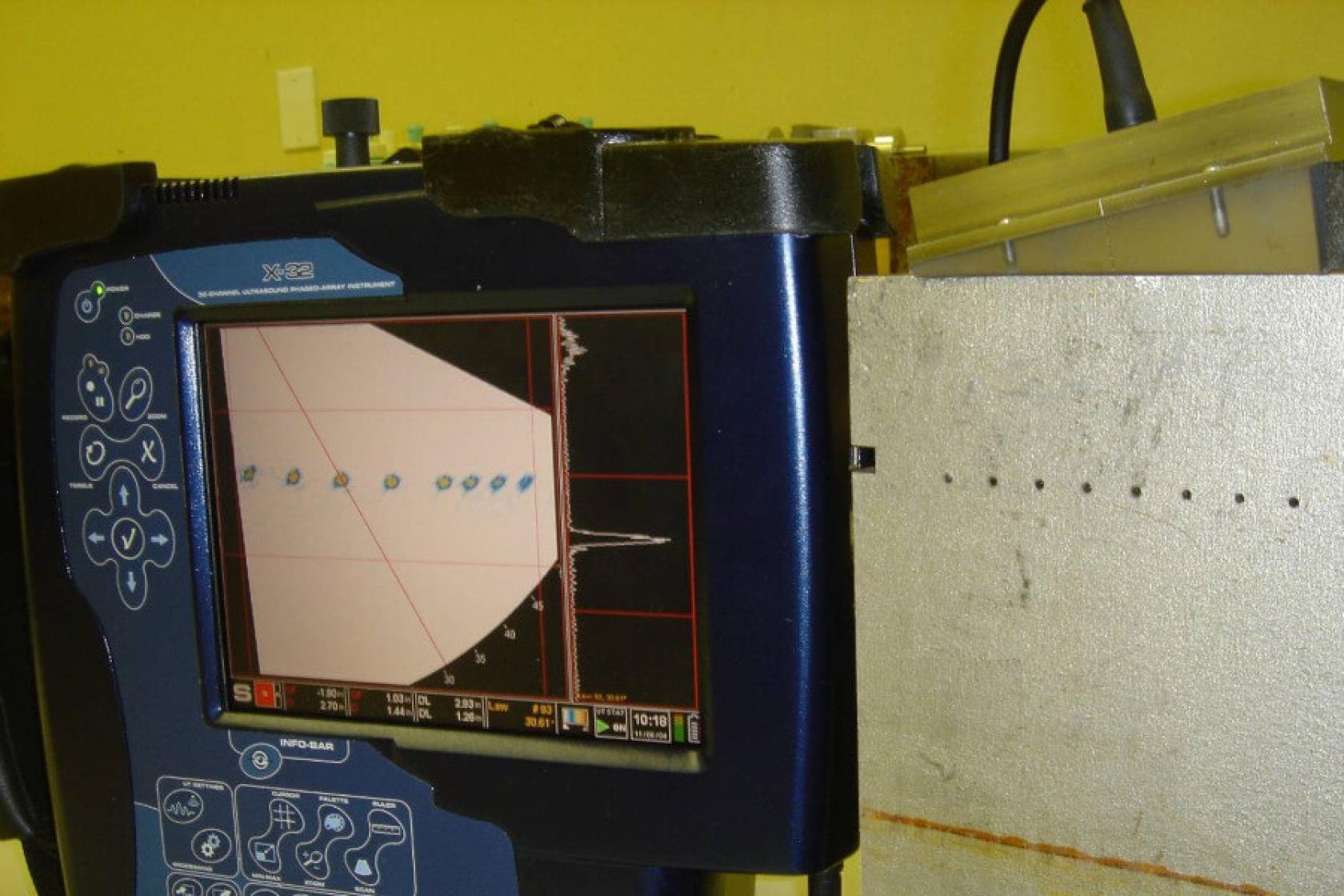

Phased-Array Technology

Contact: Mark Dennis, Program/Area Manager, mdennis@epri.com

Phased-array ultrasound technology provides a faster, more thorough technique for inspecting turbine blades, piping, reactor pressure vessels, and the inner radii of nozzles. Long used in radar, sonar, and the medical sector, its adoption into the industrial sector has been relatively slow because the equipment was large and difficult to deploy in the field. Recognizing its potential in the nuclear power industry, we spearheaded miniaturization of the technology, and have continued to pursue advances to maximize its value for nuclear inspections.

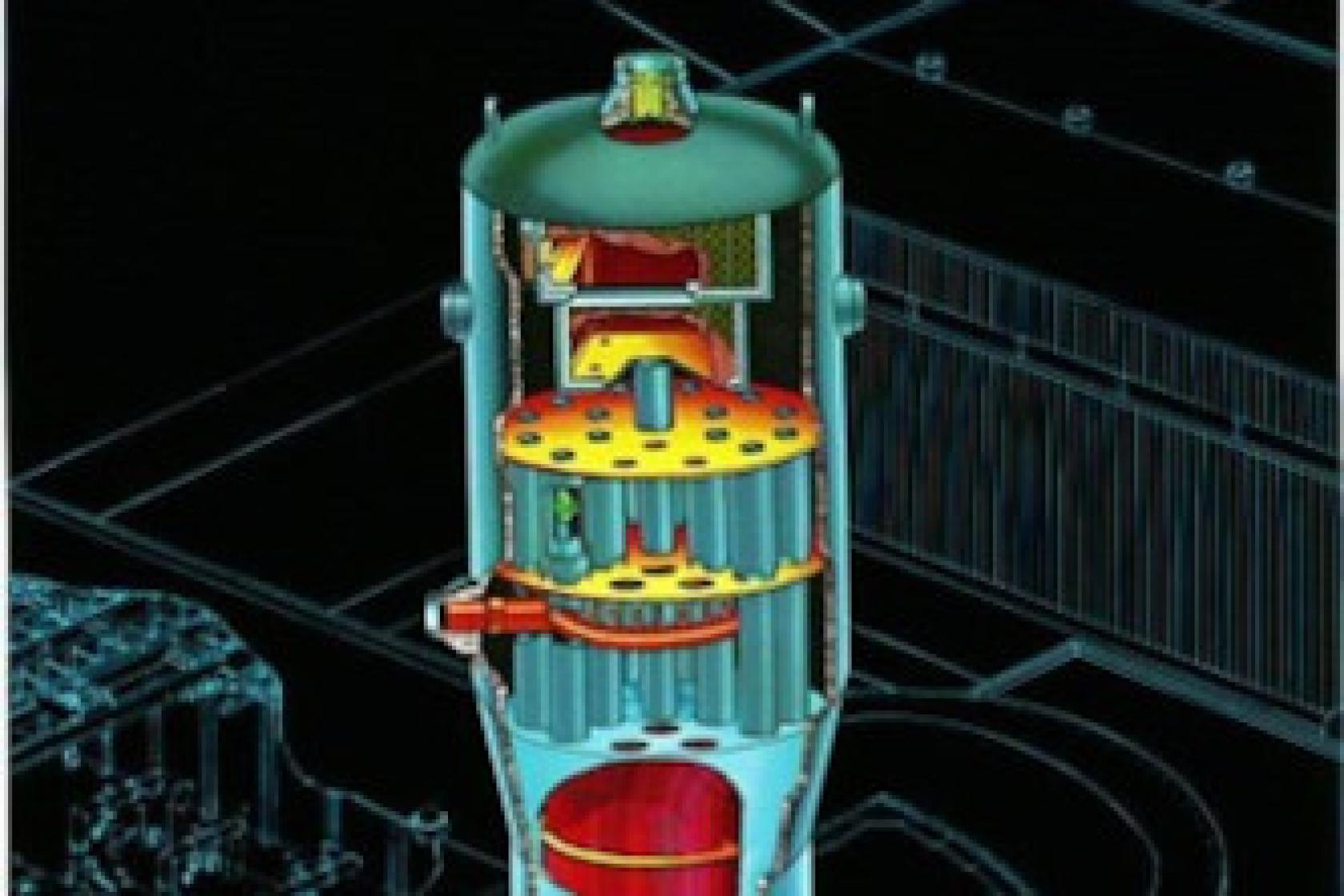

BWRVIP Laboratory (Boiling Water Reactor Vessel Internal Inspection)

Contact: Bret Flesner, Principal Technical Leader, bflesner@epri.com

The EPRI BWRVIP laboratory is used to support industry needs pertaining to the demonstration and documentation of in-vessel ultrasonic and eddy current examinations used in operating nuclear power plants. The area is also used to support R&D for BWRVIP Inspection Committee projects that address early NDE technique, equipment, and procedure development.

Equipment:

- Next Generation Ultrasonic Phased Array Device

- Zetec Topaz 64/64 Portable Phased Array System

- ATCO GPS automated 2-axis mechanical magnetic scanner

- AUT Solutions 3-Axis remote controlled magnetic crawler/scanner

- Jireh Rotix 2-Axis Nozzle Scanner

- Immersion scanning tank with integrated linear track

- High Performance Data Analysis Mobile Workstation (Laptop)

Steam Generator Management Program (SGMP) NDE Laboratory

Contact: Rich Guill, Technical Executive, rguill@epri.com

The SGMP laboratory is where qualified techniques for eddy current inspection of steam generator tubing in nuclear power plants are developed. Steam generator tubing makes up over 50% of the primary pressure boundary in a pressurized water reactor (PWR) nuclear power plant and needs to be designed with a balance of safety and thermal performance.

Equipment:

- Zetec Miz-80iD probe pusher and data acquisition system

- Corestar Omni 200 probe pusher and data acquisition system

- Zetec 10d probe pusher and associated testers and acquisition systems

- Acquisition and analysis computers

- Eddy current probes

- Various tube samples and calibration standards

- Corestar EddyPen instrument and probes

- CoreStar Cube ECT Tester with coil adapters

NDE Concrete Laboratory

Contact: Salvador Villalobos, Senior Team Leader, svillalobos@epri.com

The initiative related to nondestructive evaluation (NDE) of concrete at EPRI started in 2007. Fabricating mockups and testing the capabilities of the different commercially available NDE methods has been essential for the program. Some of the mockups available in the concrete area include: concrete affected by alkali silica reaction, concrete affected by freezing and thawing, and mockups with embedded defects (such as delamination, voids, and honeycombs).

Equipment:

- GSSI SIR-3000 Ground Penetrating Radar Inspection system + 1.6 GHz antenna

- First generation shear wave array MIRA

- Surfer UK-1401 (1st gen)

- Impact echo (Doctor – NDE 360)

- s’MASH Impulse response test system

- Elcometer Covermeter 331

- Vacuum based crawler

- Drone – DJI Phantom 4 Pro

- Drone DJI Matrice 600

- ELOP NDE Rolling Scanner

Generation NDE Laboratory

Contact: Bret Flesner, Principal Technical Leader, bflesner@epri.com

This NDE laboratory is utilized in conducting various advanced non-destrutive evaluations (NDE) activities, which focus on development of new techniques and assess the reliability of conventional and emerging NDE technologies. This laboratory focuses on NDE needs for non-nuclear power generation with a primary focus on High Energy piping and Steam Turbine NDE needs. Damage mechanisms in high temperature ferritic materials and methods to detect defects (early creep damage, thermal fatigue cracking, stress corrosions cracking, and steam turbine blade damage) are key areas of research interest.

Equipment:

- Visual Inspection

- Traditional die penetrant

- GE Mentor Visual iq

- Advanced videoscope and portable borescope

- 3D locating and measurement capability

- Dimensional scanning

- Portable Metrology (2): Laser & Blue Light

- Part-to-part inspection

- Scan-to-CAD

- Electromagnetic equipment:

- EMAT (Electro-Magnetic Acoustic Transducer)

- ACFM (Alternating Current Field Measurement)

- BFET (Balanced field Electromagnetic Techniques),

- LFET (Low Frequency Electromagnetic Testing),

- RFET(Remote Field Testing)

- 3D Scanners – Creaform 700 and GOM ATOS

- Ultrasonic Immersion Tank

- Evisive Microwave 2-Axis Table

Performance Demonstration Laboratory

Contact: Leif Esp, Program Manager, jesp@epri.com

Examination requirements in the nuclear power industry demand rigorous attention to the use and application of NDE technology. The ability to detect, size, and characterize flaws in nuclear plant materials and components provides an early warning system— often years in advance—for possible problems.

Our Performance Demonstration (PD) Laboratory provides the means by which people, procedures, and equipment are qualified to perform specific examinations required by the American Society of Mechanical Engineers (ASME), Section XI (Rules for Inservice Inspection of Nuclear Power Plant Components).

To comply with Appendix VIII of Section XI the nuclear industry established the Performance Demonstration Initiative (PDI) in the early 1990s. Based on our extensive NDE expertise and capabilities, the nuclear industry selected EPRI to develop and administer the testing program. Since then, the EPRI PD team have helped several other countries satisfy their own performance demonstration requirements, including Japan, Korea, Spain, Sweden, Switzerland, UAE and Taiwan.

EPRI's performance demonstration team has provided global support for members including:

-

Leveraging EPRI PD resources

-

Developing technical justifications to bridge differences between varying non-US qualification methodologies

-

Providing direct support in developing qualification concepts

-

Applying EPRI develop test specimen design and flaw making technology

-

Providing regulatory support

-

Facilitating technology transfer

-

Providing site support during implementation

While the Appendix VIII scope addresses only piping, pressure vessels and bolting at nuclear power plants, our Performance Demonstration Laboratory goes much further. The laboratory develops and evaluates NDE techniques encompassing reactor upper head penetrations in pressurized water reactors, boiling water reactor internals, and various advanced manufacturing applications.

Effective qualification also depends on realistic test samples. These samples encompass various weld types, different materials, assorted types of nozzles, reactor vessel sections, bolting, and piping. We benchmark these samples' NDE responses against the responses of actual flaws found in the field to ensure their applicability. Because an individual qualification test for personnel could require the use of several mockups, the ability to offer a diversity of tests is important and EPRI has them on hand.

Our inventory consists of more than 700 test samples:

An array of different components, including piping, nozzles, reactor vessel sections, and bolting

Different kinds of piping samples fabricated using various materials such as austenitic, ferritic, and nickel alloys. In addition, to standard piping welds, the program also includes weld overlay repair mock-ups for similar and dissimilar metal welds. The program also has a larger inventory of full scale clad ferritic reactor pressure vessel (RPV) mock-ups for both Pressurized Water Reactor (PWR) and Boiling Water Reactor (BWR) applications.

A range of pipe sizes, from 2" to 50"

A variety of implanted flaws—actual and simulated— including thermal fatigue cracking, mechanical fatigue cracking, and stress corrosion cracking

The centralized availability and management of hundreds of test samples means that individual nuclear power plants do not have to buy and stock their own, saving the industry an estimated $40 million.

Equipment:

-

Zetec Dynaray 256-256 element phased array UT data acquisition system

-

Zetec Dynaray Lite 64-64 element phased array UT data acquisition system

-

Zetec Zscan UT conventional UT data acquisition system (8 channel LEMO)

-

MicroTomo Conventional Encoded Ultrasonic Instruments

-

Z-Scan UT 4-Channel Conventional Ultrasonic Instrument

-

Titan data collection and analysis laptops

-

High Performance collection and analysis laptop for 3D data collection and analysis

-

High Performance collection and analysis laptops for collection of UT Simulator data files

-

High Performance Graphics Workstation to handle 3D UT Merge Data

-

6-axis robotic scanning arm and controllers

-

Custom stand for 6-axis robotic scanning arm

-

-

Stiffness and stability upgrades for RPV Upper Head Penetration Scanner

-

Mobility upgrades for scanning stations

-

Set of automated scanner guide / scanning rings - with later modifications

-

Ultrasonic Testing (UT) Simulators

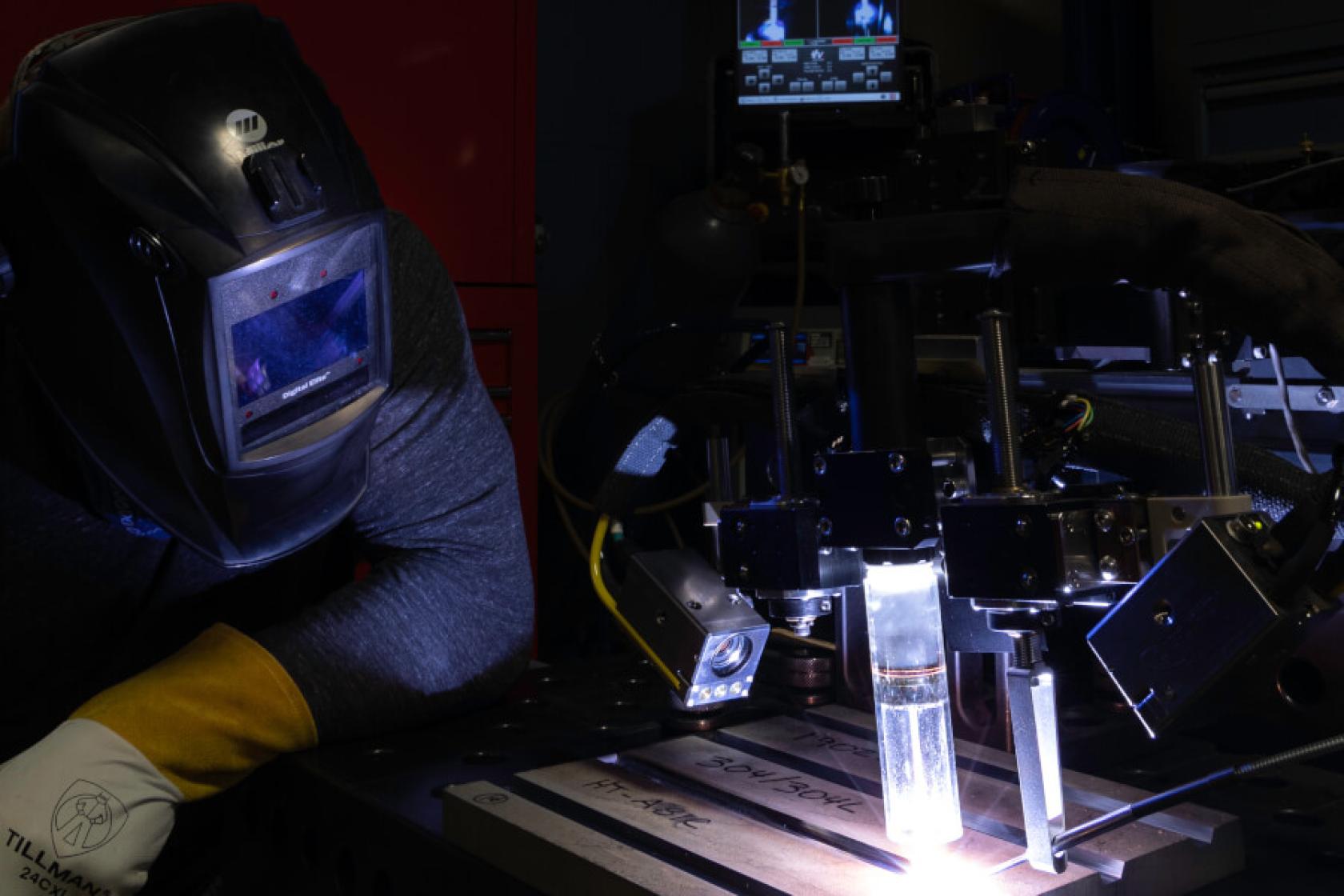

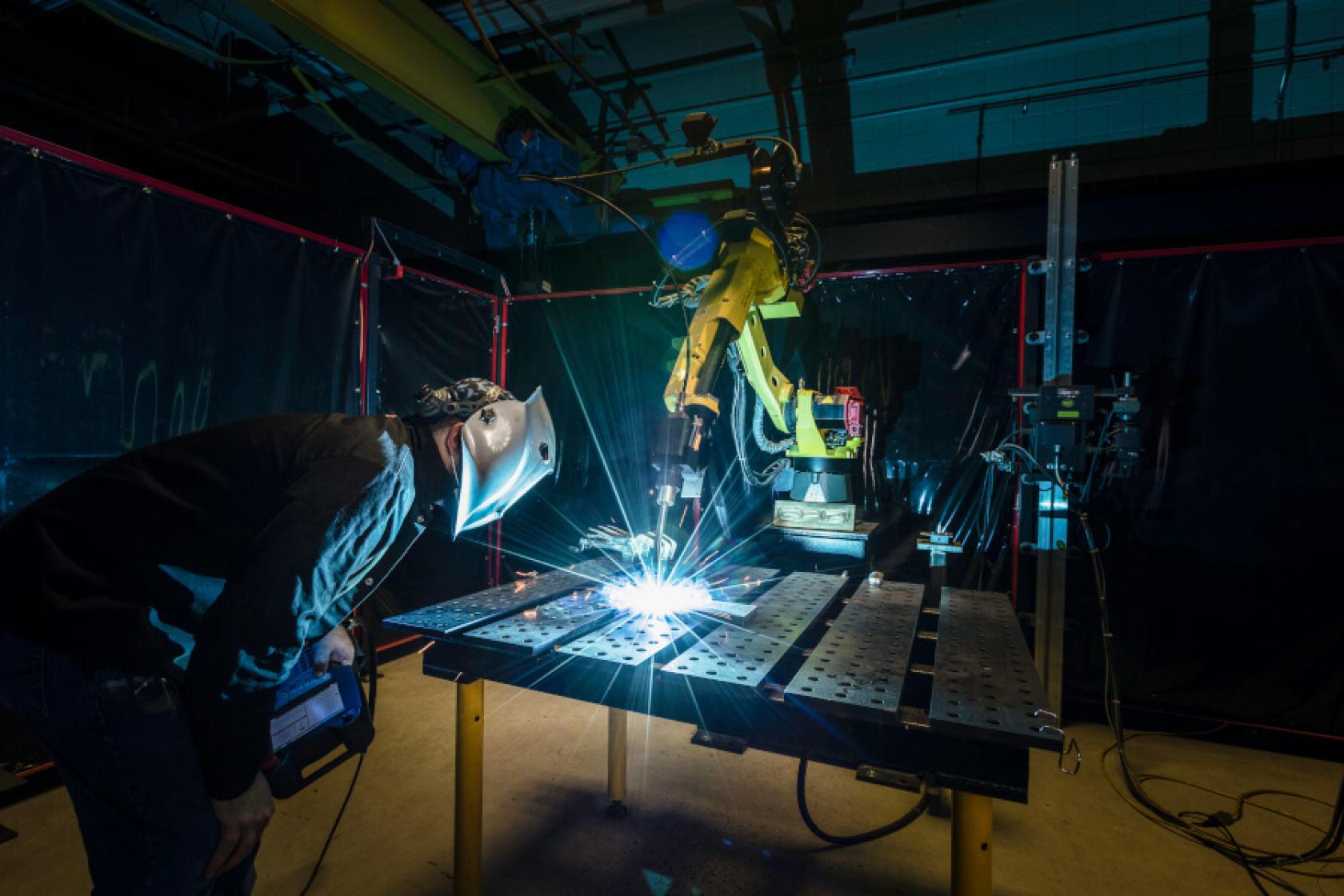

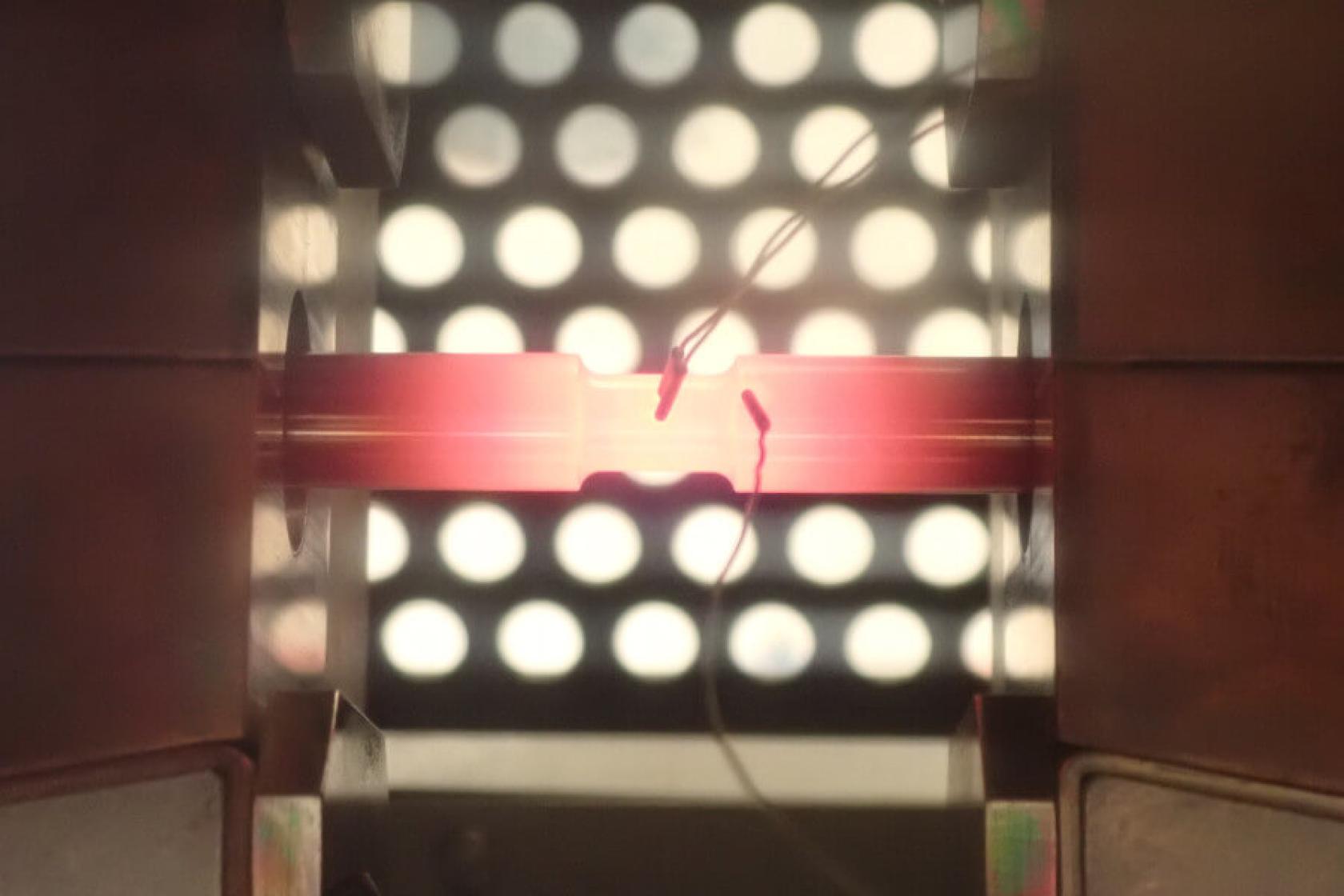

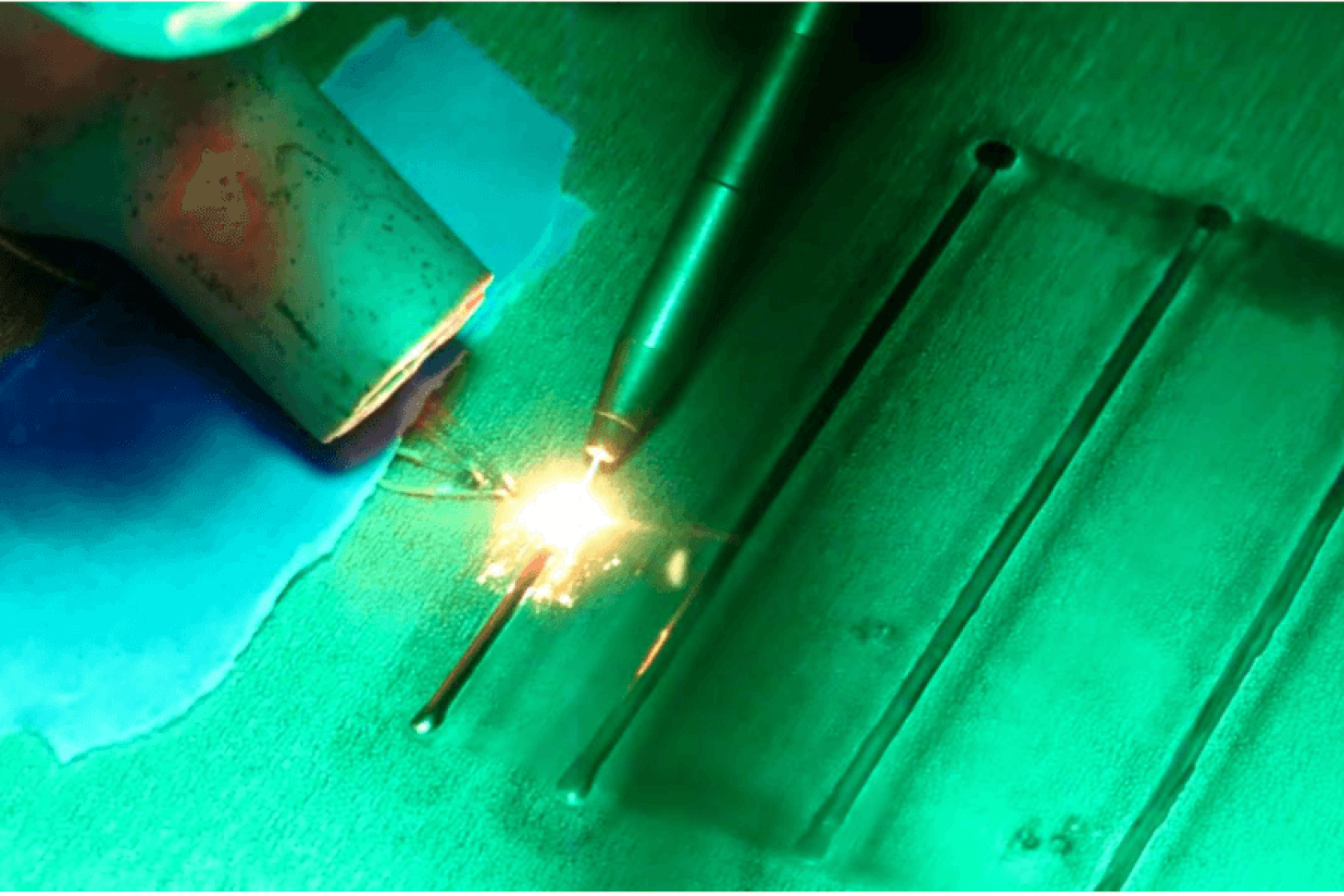

Welding Repair and Technology Center (WRTC) Laboratories

Contact: Greg Frederick, Program Manager, gfrederick@epri.com

From manual and automated welding process to material testing and characterization equipment, the WRTC laboratories are centered on evaluation technologies. Everything from manual welding processes (GMAW, SMAW, GTAW, PTAW) to mechanized and robotics systems are utilized to create representative mockups of real-world conditions in the Nuclear Power Industry. The labs also host many evaluation methods, material testing, modeling and simulation, in-situ monitoring, or post weld material processing. This facility is utilized to evaluate or develop new welding repair techniques, in-depth evaluation of fabrication methods, support of Code requirements and technical bases data, and supporting implementation of technology in the power industry.

EPRI has extensive weld, metallurgy, and mechanical laboratories necessary to conduct research across the institute. EPRI members can also request use of the various laboratories and equipment to address their specific needs. The following tables provide a summary of equipment at EPRI's welding, metallurgy, and mechanical laboratories and their primary purpose.

For additional information pertaining to the laboratory capabilities and equipment in the WRTC laboratories you can take a virtual tour of the laboratories by visiting the WRTC Welding Virtual Laboratory Tour website: wvlt.epri.com/

Equipment:

Processes: GMAW, GTAW, SMAW, PTAW

Tables, Lathes, Positioners, Track Systems, …

Saws, mill, grinders

Robotic GMAW

Welding GTAW System

High Speed Monitoring System

Monitoring system for advanced welding applications using high deposition rates (advanced

waveform gas metal arc welding)

Stock of weld consumables

(wire, stick, electrodes, powder)Arc Melting

Calorimetry

Data acquisition (high speed

cameras, temperature, etc.)ABSI Laser system

Diode Laser system

Gleeble™ Thermo-mechanical Simulator

Impact, Bend, and Hardness Tester

Weldability Assessment Tools

Cast-pin tear system

Varestraint test system

Machine GTAW System

Robotic GMAW

Gleeble Thermo-Mechanical Simulator

Manual SMAW

ABSI Laser System

Leak Sealing Demonstrations

Laser Ablations of Additive Component

Diode Laser Cladding

Instrument & Control (I&C) and Cyber Security OT Laboratory

Contact: Michael Thow, Program Manager, mthow@epri.com

Focusing on digital Operations Technology (OT) equipment commonly found in nuclear and generation power plants. It enables the investigation of equipment and processes related to instrumentation and control (I&C) or those areas that have a nexus to I&C to the benefit of EPRI’s membership and collaborators. Example research that is conducted in the lab includes cyber security research, wireless technologies, robotic characterization, OT equipment development and analysis, security control method efficacy, digital twin technologies, and supporting external collaboration.

The lab primarily is comprised of digital OT equipment and the EPRI flow loop. The digital OT equipment consists of servers, networking equipment (both wired and wireless), fireware, and programmable logic controllers that emulate the process environment typically found in power generation facilities, both nuclear and non-nuclear. The heavy use of virtualization allows for a reduced footprint without sacrificing research capabilities.

The EPRI flow loop is comprised of two flow loops, a one-inch diameter loop and a three-inch diameter, that can operate independently from each other or be cascaded together. Each loop consists of a holding tank, pump, valves, and instrumentation. Additionally, the one-inch diameter loop has a heater installed to allow for temperature gradients. The flow loop uses flanges to allow for easy replacement of components or to install additional sections to facilitate future research.

Capability:

- PLCs, transmitters, controllers, pumps, valves, motors, etc.

- Flexible, virtualized networks to support multiple ongoing test setups.

- Wireless I&C testing and security.

- Cyber security tools, appliances, and software

Equipment:

- Flow loop

- PLC cabinet

- Allen Bradley

- Siemens

- NI

- Distributed Antenna System

- Networking Equipment

Our Central Labs

Machine Shop

EPRI’s machine shops manages the complete spectrum of machining needs as a central resource with a focus on high-precision machining of mechanical testing samples, production of NDE test samples, extraction of metallurgical characterization samples, weld joint and sample preparation, fabrication of bespoke testing and experimental equipment, 3-D design, and dimensional verification.

Capabilities & Equipment

-

Portable Plunge Electro Discharge Machine (EDM)

-

Sharp 300 Sinker EDM

-

Sodick K1C Small Hole Drilling Machine

-

(3) Sodick Wire EDMs

-

Haas ST-25 CNC Multi-tool Lathe

-

Haas TL-3 CNC Lathe

-

Haas VF-2 CNC Mill

-

Manual Machining: milling, turning, bandsaw, grinding, sandblasting

-

Solidworks Design and Solidcam Software

-

Keyence Optical Comparator

-

Calibrated manual measurement equipment

Laboratory Supports Research on

Materials, Pressure Parts, Renewables, Turbines, Welding & Repair, Advanced Nuclear Technology, Non Destructive Evaluation, Transmission & Distribution

High Bays

EPRI’s two high bays are uniquely suited to serve the Charlotte site and all groups (Generation, Nuclear, and ED&CS) with handling of large materials and equipment, initial inspections, and configurable temporary large scale laboratory experiments in addition to supporting long-term climate controlled storage of critical items.

Capabilities & Equipment

-

15 ton overhead cranes for receipt and placement of incoming materials, powerplant equipment, and components

-

Two large bandsaws for initial sectioning of materials and components

-

>10,000 sq. ft. of configurable laboratory space for inspections of incoming material, short-term experiments, and critical long-term experiments and demonstration projects

-

High capacity racks and for climate controlled storage of materials, components, and equipment supported by a laboratory information management system

Laboratory Supports Research on

Materials, Pressure Parts, Renewables, Turbines, Welding & Repair, Advanced Nuclear Technology, Non Destructive Evaluation, Transmission & Distribution