Generation and Low-Carbon Resources Laboratories

With more than 20 unique capabilities, EPRI's Generation laboratories provide world-class expertise to address the most challenging research questions for ensuring safe, reliable, affordable, and clean electricity in today’s power plants. Core laboratory competencies span materials science, material testing & characterization, chemistry & corrosion, welding, non-destructive evaluation, and digitization, enabling expert staff to conduct cutting-edge research to inform the future energy supply.

EPRI's Generation laboratories are foundational to the value EPRI provides our members and ultimately, society. Our staff offer subject matter expertise and experience across the spectrum of lab operations including responding to component failures, conducting targeted chemistry studies to optimize water treatment approaches in a complex changing environment, assessing cyber security threats to power plant control systems, and conducting multi-year high-temperature studies on new advanced manufacturing methods and materials for future generation technologies.

Laboratory Contacts:

- General Inquiries: John Shingledecker, Principal Technical Executive Generation, jshingledecker@epri.com

- Materials Testing & Characterization: John Siefert, Area Lead Materials, Generation, jsiefert@epri.com

- Chemistry: Kirk Ellison, Area Lead Water Manager & CCPs, kellison@epri.com

Inside EPRI’s Generation Labs is your backstage pass to the cutting-edge work powering tomorrow’s energy systems. In this four-part video series, meet the engineers and researchers turning complex challenges into actionable insights—right from EPRI’s own Generation laboratories. Don’t miss these short, high-impact videos and the researchers behind the scenes. Watch how science in the lab is shaping energy in the field.

Electrolysis and the Water-Energy Nexus

Smarter hydrogen starts with better data—watch how EPRI research is shaping the water-energy nexus. Take an inside look at how EPRI is uncovering what makes electrolysis systems more durable, efficient, and ready for renewables.

Accelerating Deployment of Plant Controls through Advanced Simulation Environments

Today’s power plants need to be flexible, fast, and reliable. EPRI’s virtual testing environments help utilities validate control upgrades without the risk or cost of trial-and-error. From changing ramp rates to real-world results—watch how simulation is accelerating smarter operations.

Reducing Rotor Life Extension Risk Through Material Analysis

Gas turbines are facing more starts, stops, and stress than ever before. In this video, find out how EPRI’s long-term testing reveals how materials perform under real-world operating conditions. The result: extended asset life, improved reliability, and lower energy costs.

Integrated Life Management of Wind Turbine Bolts

Wind turbines rely on hundreds of bolts—and one small failure can have a big impact. Find out how EPRI’s research digs deep into materials, design, and maintenance to boost turbine reliability. From the lab to field, this work helps keep renewable power affordable, reliable, and resilient.

Laboratories Led by Our Expert Generation Staff

High Temperature Mechanical Testing Laboratory

This laboratory supports the development of high temperature test data to assess new material development, life management of existing components or systems, advanced manufacturing processes, and supports the enhancement of codes and standards requirements.

Capabilities & Equipment

- >60 high temperature uniaxial creep frames for isothermal creep testing to 2,000°F (1100°C) at loads ranging from 600 to 50,000 lb-f

- 2 impression creep frames for small sample testing to obtain comparable creep rates to uniaxial tensile specimens

- Mobile potential drop monitoring equipment for creep crack growth experiments outfitted to one of the creep frames

- High temperature tribometer for wear testing

This Laboratory Supports the following EPRI Research Areas

Materials, Pressure Parts, Steam Turbines, Gas Turbines, Welding & Repair, Advanced Nuclear Technology, Advanced Manufacturing, Petrochemical and Low-Carbon Energy, Codes and Standards

Multiaxial Testing Laboratory

This laboratory supports high temperature testing of pressurized vessels with or without end load to evaluate the effects of multiaxial loading. This testing provides realistic loading scenarios to assess the performance of in-service components and is one of a handful of similar facilities anywhere in the world.

Capabilities & Equipment

- 6 large box furnaces for pressurization testing of smaller tube samples (≤2.5-inch [65 mm] OD X 18-inch [455 mm] long) to 2,000°F (1,100°C)

- 2 very large furnaces for pressurization of larger tubes samples (≤5-inch [125 mm] OD X 36-inch [1 m] long) to 2,000°F (1,100°C)

- 4 very large 50,000 lb-f creep frames for pressurization + end load creep testing of large full-size tubing components taken from ex-service power plant components or fabricated onsite using supporting EPR laboratories

- Pressurization is typically performed using a 95% Ar + 5% He gas for He-leak detection, and with assistance from a booster pump to provide an internal pressure <20,000 psi (1,375 bar).

This Laboratory Supports the following EPRI Research Areas

Boilers, HRSGs, Piping, Welding & Repair, Advanced Nuclear Technology, Advanced Manufacturing, Petrochemical and Low-Carbon Energy, Codes and Standards

Materials Preparation Laboratory

This laboratory contains state-of-the-art equipment for the preparation of materials relevant to energy transition. Combined with well-informed procedures, a wide range of materials are prepared daily for the purposes of detailed metallurgical evaluation and advanced characterization.

Capabilities & Equipment

Sample preparation

- Sectioning: Abrasive saw and precision saw to make small cuts on samples

- Mounting: (to encase samples for polishing): Four hot mounting machines and one cold mounting vacuum chamber

- Polishing: (large macro samples, hot and cold mounted samples of various sizes): Two automated polishers and one semi-automated polisher

- Fine-polishing: One vibromet system for producing very high quality surface finishes such as might be required for evaluation using scanning electron microscopy or electron backscatter diffraction

Imaging:

- Digital camera for sample intake, documentation and macro-imaging. Images can also be used to reconstruct as-received parts using photogrammetry software.

- Light optical microscope for quality assurance

- Stereoscope for macro analysis

Analysis

- Optical emission spectroscopy for composition analysis

This Laboratory Supports the following EPRI Research Areas

Materials, Pressure Parts, Steam Turbines, Gas Turbines, Welding & Repair, Advanced Nuclear Technology, Advanced Manufacturing, Petrochemical and Low-Carbon Energy

Advanced Materials Characterization Laboratory

This laboratory provides state-of-the-art advanced characterization tools for the purpose of evaluating the microstructure of materials and linking the observed features to long-term temperature effects, damage, and/or processing-related phenomenon. The capabilities available to EPRI researchers in this space are routinely used to evaluate ex-service components, perform failure analysis, and complement a wide range of active research studies across the institute.

Capabilities & Equipment

- LED microscope for large area imaging and 3D surface reconstruction

- Digital optical microscopes capable of a 20X to 6000X magnification for microstructure imaging and 3D surface reconstruction

- Laser microscope for 3D high-resolution surface reconstruction, profilometry and surface imaging.

- Two state-of-the-art scanning electron microscopes with multiple in-lens detectors capable of high-resolution imaging to 150,000X magnification and mounted to automated stages with supporting software to collect hundreds or thousands of images in a prescribed pattern for analyzing statistically relevant datasets.

- Two EDS detectors for near-surface elemental analysis

- Two EBSD detectors for phase, grain boundary, texture and local surface strain analysis

- Benchtop Micro-XRF for very large-area elemental distribution analysis

This Laboratory Supports the following EPRI Research Areas

Materials, Pressure Part, Gas & Steam Turbines, Renewable Energy, Welding & Repair, Advanced Nuclear Technology, Advanced Manufacturing, Petrochemical and Low-Carbon Energy, Power Delivery (Transmission & Distribution), Non-Destructive Evaluation

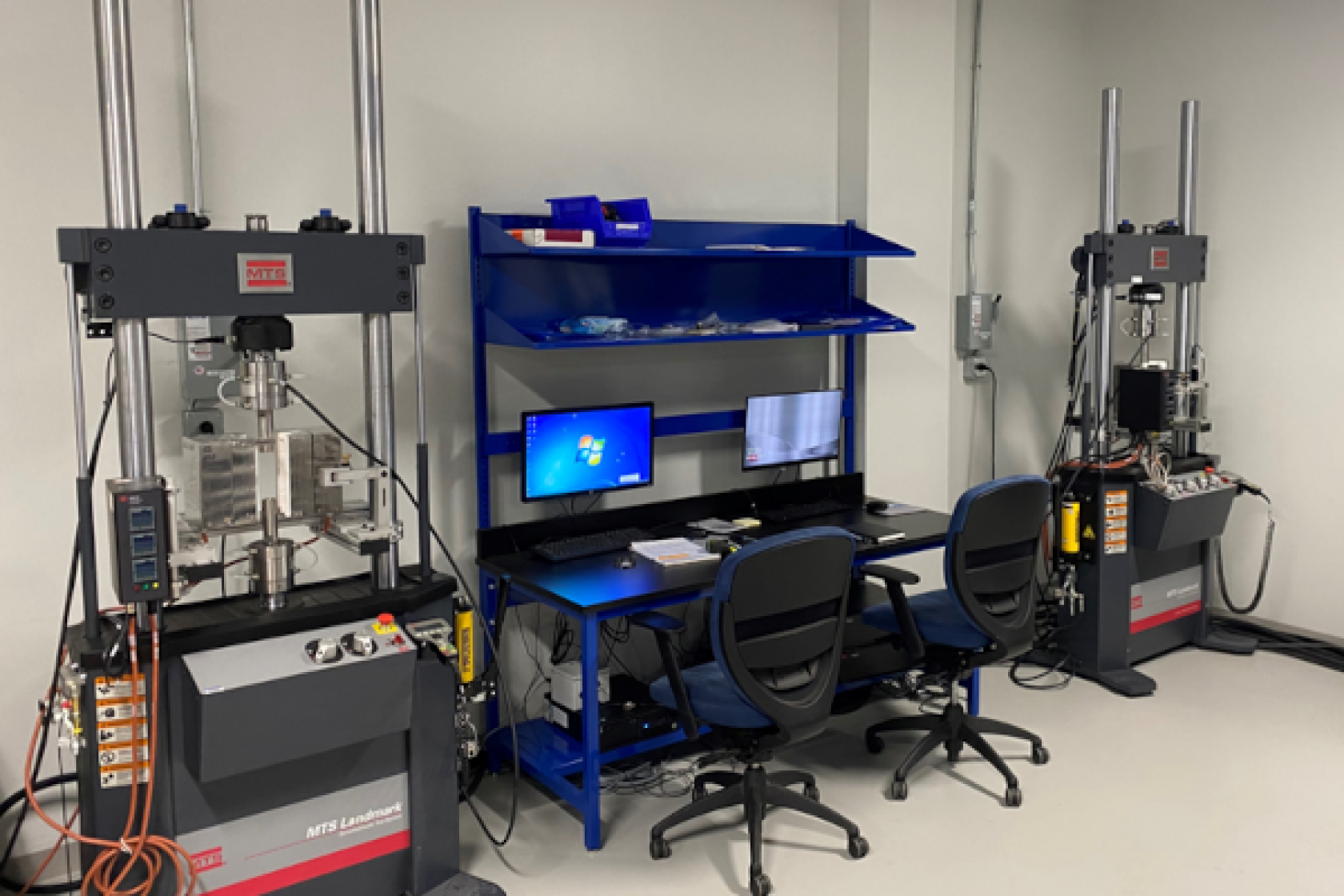

High Temperature Cyclic Testing Laboratory

This laboratory conducts room and high-temperature tensile, low-cycle fatigue, high-cycle fatigue, fatigue with hold time, fatigue crack growth, fracture toughness, and/or feature-type tests.

Capabilities & Equipment

- MTS Landmark 370.10 servohydraulic load frames

- Apply monotonic and cyclic loading

- 100kN (22kip) capacity

- MTS 653 High Temperature Furnaces

- Isothermal specimen heating to 2,550°F (1,400°C)

- MTS 632 Axial Extensometry

- Measure axial strain of test specimens

- MTS FlexTest 40 Controllers + MulitPurpose Elite

- Programmatic control of experiments and data acquisition

Laboratory Supports Research on

Materials, Pressure Parts, Steam Turbines, Gas Turbines, Welding & Repair, Advanced Nuclear Technology, Petrochemical and Low-Carbon Energy

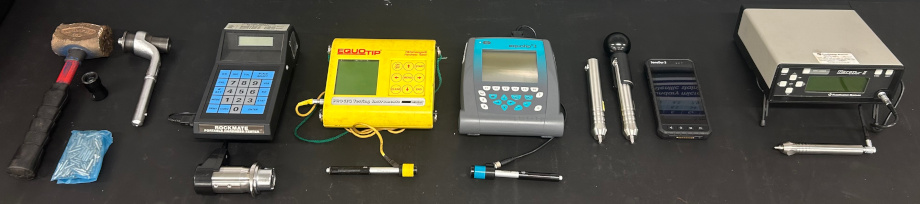

Hardness Testing Laboratory

This laboratory evaluates the distribution of hardness at the micro- or macro-scale for commonly utilized hardness testing methods. The facilities are routinely used to assess welded components taken from power plants, oil and gas components, and failures.

Capabilities & Equipment

- Four Vickers microhardness testers for large area microhardness distribution mapping of complex cross sections. The testers can generate 10,000 indents/day and are capable of generating single maps >20,000 indents.

- Knoop microhardness indentation for testing thin films, coatings or other features that cannot be easily evaluated with Vickers indentation.

- Manual Brinell hardness tester with load capacity of 62.5 to 3000 kgf

- Manual Rockwell hardness tester with load capacity of 1 to 187.5 kgf

- Commonly utilized field hardness equipment including ultrasonic contact impedence (UCI), rebound, and shear-pin Brinell

This Laboratory Supports the following EPRI Research Areas

Materials, Pressure Part, Gas & Steam Turbines, Renewable Energy, Welding & Repair, Advanced Nuclear Technology, Advanced Manufacturing, Petrochemical and Low-Carbon Energy, Power Delivery (Transmission & Distribution)

High Temperature Heat Treatment and Aging Laboratory

This laboratory supports the heat-treatment of materials and welds in laboratory, simulated field environments, and subjects samples to long-term (accelerated) aging, supporting life management of powerplant materials and components.

Capabilities & Equipment

- 12 small furnaces with a maximum temperature of 2,190°F (1,200°C) and an interior volume of 10 X 10 X 15-in. (255 X 255 X 380 mm)

- 1 medium furnace with a maximum temperature of 2,190°F (1,200°C), an interior volume of 9 X 12 X 15-in. (230 X 305 X 380 mm), and outfitted with atmospheric control.

- 1 large furnace with a maximum temperature of 2,300°F (1,250°C) and an interior volume of 26 X 28 X 45-in. (660 X 710 X 1,145 mm)

- 1 small tube furnace with a maximum temperature of 2732°F (1,500°C) with a 2” (50.4mm) diameter capable of inert gas or vacuum operation

- 2 convection ovens with a maximum temperature of 1,000°F (538°) and an interior volume of 11 X 11 X 11-in. (280 X 280 X 280 mm)

- 2 convection ovens with a maximum temperature of 650°F (343°C) and an interior volume of 18 X 24 X 20-in. (455 X 610 X 510 mm)

- Quench Tank and handling equipment

- Field Equipment: ceramic resistance heating pads, induction heating equipment, and data loggers for attaching dozens of thermocouples to the experiment.

This Laboratory Supports the following EPRI Research Areas

Materials, Pressure Part, Gas & Steam Turbines, Renewable Energy, Welding & Repair, Advanced Nuclear Technology, Advanced Manufacturing, Petrochemical and Low-Carbon Energy, Power Delivery (Transmission & Distribution), Non-Destructive Evaluation

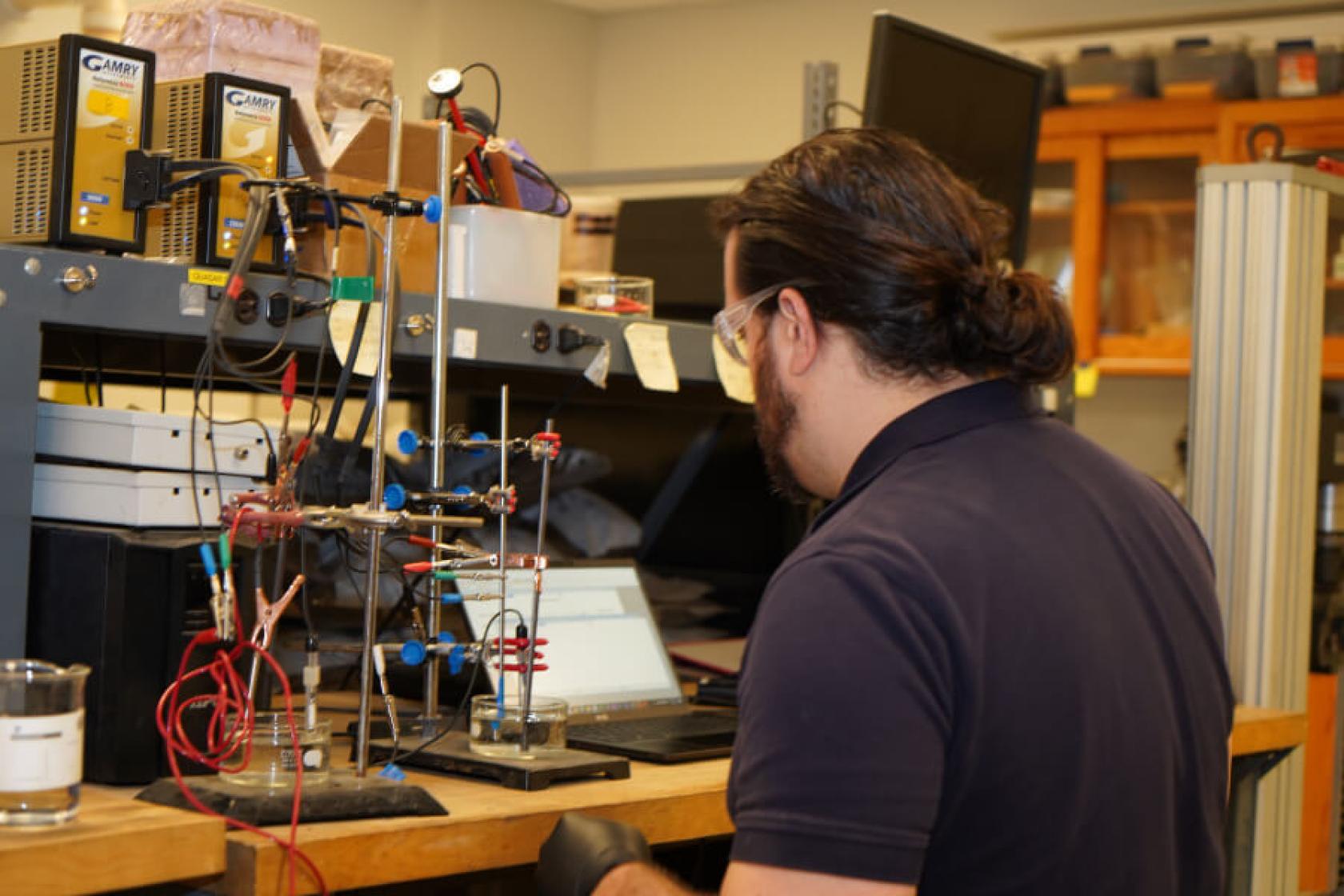

Water Chemistry and Corrosion Laboratory

Applied science & engineering laboratory to support industry needs for water chemistry, treatment, and corrosion. Laboratory focus includes enabling long-term plant operations, legacy water management, assessment of new water treatment technologies, materials selection, and understanding water implications of the energy transformation.

Capabilities & Equipment

-

TXRF: Provides fast, highly sensitive, non-destructive, and quantitative multielement analysis of trace elements in liquids, powders and suspensions.

-

Spectrophotometer: Assist in the determination of specific organic compounds, metals, turbidity, chlorine, etc. in water samples based on their light absorption characteristics.

-

Reverse Osmosis Membrane Modules: Operates on both full-scale membrane modules and test scale flat sheet membranes. Supports development of membrane processes via filtration and retention tests on many types of membranes and waters for myriad applications.

-

RO Spotlight: Real-time online monitoring of RO membrane systems to detect mineral scale and fouling and assess the effectiveness of mitigation strategies.

-

Cognex vision system: Commercial machine vision system with integrated image recognition AI algorithm for automated visual inspection of plant processes.

-

OLI Software Suite: Predict & model electrolyte chemistry, mineral scaling and corrosion behavior over a broad range of operating conditions. Reduce cost of experiments and accelerate designs with virtual chemistry lab simulations, design optimal operating windows to improve operations performance and sustainability.

-

Chemical and electrocoagulation setups: Jar tester, electrochemical cells and potentiostat. Test different concentrations of coagulant to obtain optimum flocculation at minimal cost and how well the suspended solids can mix with a liquid.

-

Rotary evaporator: Facilitates in depth evaluation of constituent partitioning and volatilization in evaporative volume reduction processes

-

Brine Management & Encapsulation: Rheometer, calorimeter, curing chamber, and mix development hardware. Support sample preparation and bench scale testing to determine physical and mechanical properties of flowable materials for mix design and development in encapsulation studies.

-

Corrosion: Potentiostats & multiplexers, rotating cage (RCA) and C-ring autoclaves, electrochemical and immersion test cells, etc.: Routinely perform short- and long- term corrosion immersion testing on metallic, nonmetallic and coated materials, as well as conventional and advanced electrochemical testing developed for the assessment of corrosion rates, crevice and pitting corrosion.

-

Climate control chamber: Provides a controlled/stable environment that simulates the relative humidity (RH) and temperature exposure cycles of specific atmospheric conditions to assess and predict the susceptibility of engineering materials to atmospheric corrosion.

This Laboratory Supports the following EPRI Research Areas

Water Treatment Technologies, Boiler and Turbine Steam and Cycle Chemistry, Coal Combustion Products Management, CCP Land and Groundwater Management, Materials, and Low-Carbon Energy

Operational Technology (OT) and Digitalization Laboratory

Cross-sector capable lab space dedicated to enhancing and informing instrumentation and control, cyber security, digital technologies and IT/OT convergence in cyber-physical systems.

Capabilities & Equipment

- Virtualized Network: Ability to simulate and test virtualized network capabilities with cyber physical components as well as provide resources for parallel projects.

- Flow Loop: Testbed consisting of cyber-physical equipment that is commonly found in generation plants (valves, pumps, motors, heaters, instrumentation, and a DCS/PLC architecture).

- DCS/PLC: several DCS and PLC based solutions with full control and software functionalities to test control modifications and optimization techniques on physical systems.

- Communications Testbed: Focusing on wired and wireless communications and cyber security equipment to create and modify communications networks including VHF, UHF packet radio, Wi-Fi 6E 802.11ax, sub-GHz ISM, industrial wireless (wireless HART), software defined networking, virtualized infrastructure.

- Digital Technologies: Capabilities to develop software, content, and cyber-physical proofs-of-concept/demonstrations that simulate and modeled after real industry applications. These include digital worker, unmanned autonomous vehicles, robotics, augmented reality, virtual reality, and other digital transformation equipment.

This Laboratory Supports the following EPRI Research Areas

Cyber security, process control and automation, monitoring and data analytics, digital worker, digital transformation

Laboratories Collaborating With Nuclear Staff

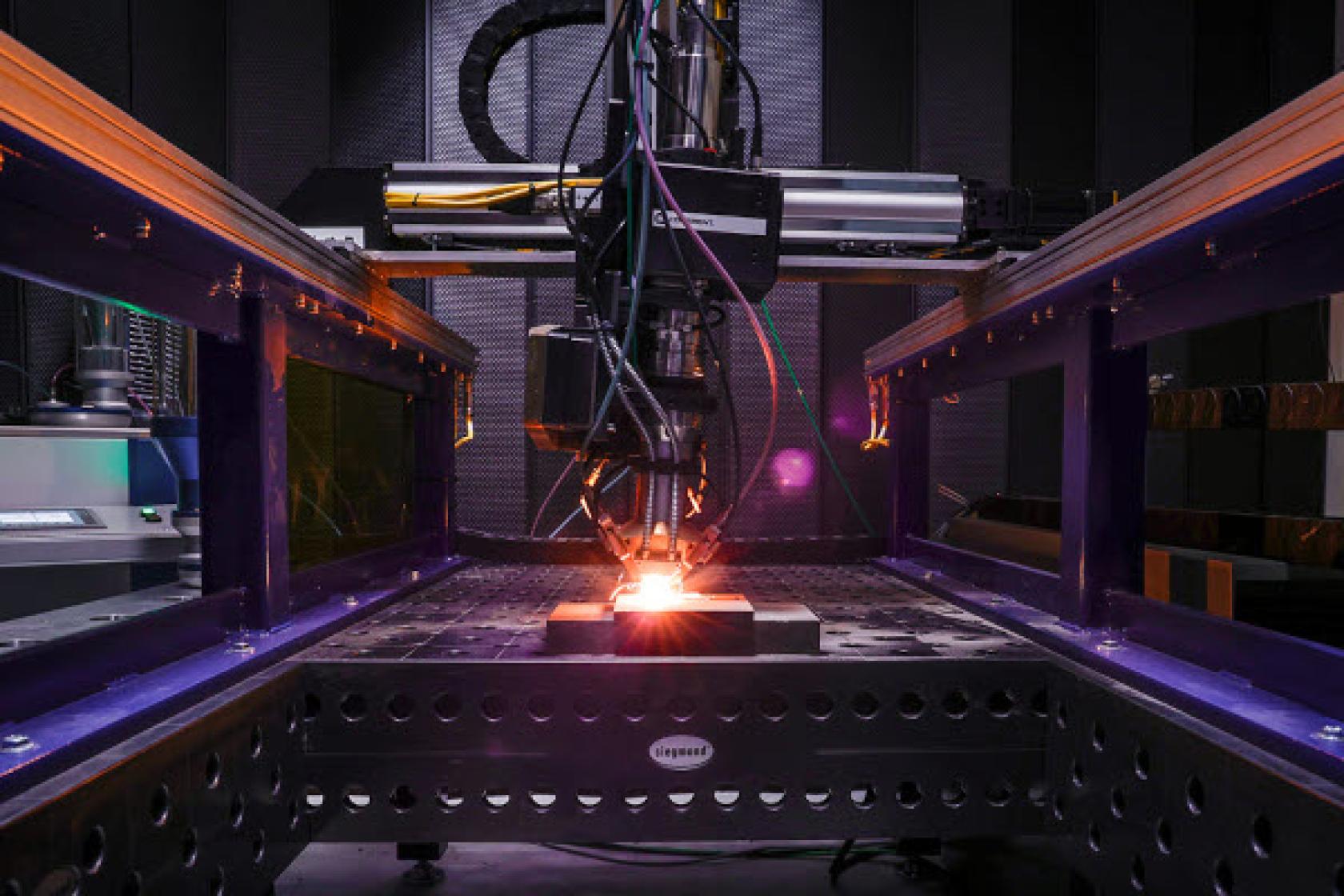

Welding Repair and Technology Center (WRTC) Labs

From manual and automated welding process to material testing and characterization equipment, the WRTC labs are centered on evaluation technologies. Everything from manual welding processes (GMAW, SMAW, GTAW, PTAW) to mechanized and robotics systems are utilized to create representative mockups of real-world conditions in the nuclear power industry. The labs also host many evaluation methods, material testing, modeling and simulation, in-situ monitoring, or post weld material processing. This facility is utilized to evaluate or develop new welding repair techniques, in-depth evaluation of fabrication methods, support of Code requirements and technical bases data, and supporting implementation of technology in the power industry.

Generation NDE Lab

This NDE lab is utilized in conducting various advanced non-destructive evaluations (NDE) activities, which focus on development of new techniques and assess the reliability of conventional and emerging NDE technologies. This lab focuses on NDE needs for non-nuclear power generations with a primary focus on High Energy piping and Steam Turbine NDE needs. Damage mechanisms in high temperature ferritic materials and methods to detect defects (early creep damage, thermal fatigue cracking, stress corrosion cracking, and steam turbine blade damage) are key areas of research interest.

Performance Demonstration Lab

Quality control requirements in the nuclear power industry demand rigorous attention to the use and application of NDE technology. The ability to detect, locate, and characterize subsurface indications in nuclear plant materials and components provides an early warning system— often years in advance—for possible problems. Our Performance Demonstration Lab provides the means by which people, procedures, and equipment are qualified to perform a specific inspection job as required by Section XI (Rules for Inservice Inspection of Nuclear Power Plant Components) of the ASME Boiler and Pressure Vessel code.

Our Central Labs

Machine Shop

EPRI’s machine shops manages the complete spectrum of machining needs as a central resource with a focus on high-precision machining of mechanical testing samples, production of NDE test samples, extraction of metallurgical characterization samples, weld joint and sample preparation, fabrication of bespoke testing and experimental equipment, 3-D design, and dimensional verification.

Capabilities & Equipment

-

Portable Plunge Electro Discharge Machine (EDM)

-

Sharp 300 Sinker EDM

-

Sodick K1C Small Hole Drilling Machine

-

(3) Sodick Wire EDMs

-

Haas ST-25 CNC Multi-tool Lathe

-

Haas TL-3 CNC Lathe

-

Haas VF-2 CNC Mill

-

Manual Machining: milling, turning, bandsaw, grinding, sandblasting

-

Solidworks Design and Solidcam Software

-

Keyence Optical Comparator

-

Calibrated manual measurement equipment

Laboratory Supports Research on

Materials, Pressure Parts, Renewables, Turbines, Welding & Repair, Advanced Nuclear Technology, Non Destructive Evaluation, Transmission & Distribution

High Bays

EPRI’s two high bays are uniquely suited to serve the Charlotte site and all groups (Generation, Nuclear, and ED&CS) with handling of large materials and equipment, initial inspections, and configurable temporary large scale laboratory experiments in addition to supporting long-term climate controlled storage of critical items.

Capabilities & Equipment

-

15 ton overhead cranes for receipt and placement of incoming materials, powerplant equipment, and components

-

Two large bandsaws for initial sectioning of materials and components

-

>10,000 sq. ft. of configurable laboratory space for inspections of incoming material, short-term experiments, and critical long-term experiments and demonstration projects

-

High capacity racks and for climate controlled storage of materials, components, and equipment supported by a laboratory information management system

Laboratory Supports Research on

Materials, Pressure Parts, Renewables, Turbines, Welding & Repair, Advanced Nuclear Technology, Non Destructive Evaluation, Transmission & Distribution