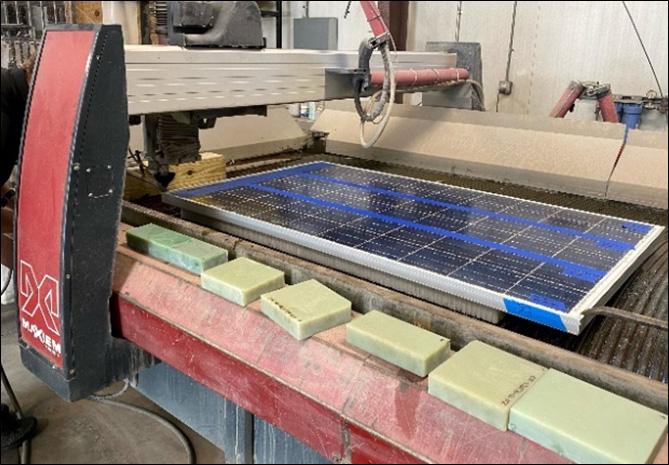

Waterjet cutting of a PV module for toxicity characteristic leaching procedure testing

Project Highlights

- Reduce risk and cost associated with EOL management of PV modules

- Investigate the impacts of operational and environmental stresses and aging on the leaching behavior of PV modules

- Explore alternatives to ASTM E3325–21 standard practice for PV module sampling and the toxicity characteristic leaching procedure (TCLP) for hazardous waste determination

- Research the prevalence of lead and other potentially hazardous materials in PV modules.

- Expand EPRI’s TCLP database with modules that have been aged naturally in the field or undergone stress testing

Background, Objectives, and New Learnings

Photovoltaic (PV) module waste volumes are expected to increase dramatically over the coming decades. Estimates are that there will be more than 60 million metric tons globally by 2050 according to reports by the International Energy Agency and the International Renewable Energy Agency.

The objectives of this project are to identify environmental stressors and aging impacts on PV module leaching behavior, determine the leaching potential of broken or damaged PV modules, and investigate alternative methodologies for hazardous waste determination in lieu of the Toxicity Characteristic Leaching Procedure (TCLP). In the United States, generator knowledge, and total analysis, are two U.S. Environmental Protection Agency (EPA) approved pathways that can be used in lieu of TCLP, but there has been little exploration of applying these methods to PV modules.

PV modules in the U.S. must not exceed certain leaching thresholds for lead, cadmium and six other metals in the TCLP Method 1311, as well as any applicable state protocols, in order to be disposed of in a non-hazardous landfill. Hazardous waste determinations are also a prerequisite for PV module recycling in most states. If module leachate concentrations exceed the TCLP test leaching thresholds, the modules are classified as “hazardous waste” and must go through a more onerous and expensive disposal process. Similar requirements and restrictions are in place globally.

This work aims to streamline hazardous waste determinations, a critical aspect of PV module end-of-life (EOL) management, by exploring methods that could reduce uncertainty, cost, and time requirements. Additionally, EPRI seeks to develop knowledge critical for assessing the potential risks of PV module leaching. The potential public benefits include improving the industry’s understanding of waste management options and supporting the sustainable deployment of solar PV systems globally.

Benefits

This project is highly relevant to utilities and the solar PV industry. Depending on the specific tasks executed, the benefits may include:

- Reduction in overall PV project costs by streamlining hazardous waste determinations, thereby lowering long-term investment risk

- Development of alternatives to ASTM E3325–21 standard practice for PV module sampling for the TCLP test

- Providing factual data to inform regulators and policymakers entrusted with ensuring safe and environmentally responsible PV technology and EOL practices

- Enhanced understanding of aging and environmental impacts on leaching behavior of PV modules

- Providing leach testing results for PV modules that are broken or damaged and have been naturally or artificially aged or exposed to environmental stressors.

Project Approach and Summary

Previous EPRI research suggests a scalable solution is needed for making hazardous waste determinations, rather than testing individual modules. Past projects identified R&D opportunities, such as understanding the effects of environmental stressors, module age, and module damage on TCLP results, evaluating alternative methods for hazard waste determinations, and assessing the potential for leaching from intact or damaged PV modules.

The project expects to use natural PV module aging through exposure to environmental stressors over time, as well as artificial aging through stress testing followed by leach testing. This should reveal potential changes in leaching behavior during the PV module service life compared to new modules. Additionally, novel approaches to understanding module composition, such as X-ray fluorescence, scanning electron microscopy, energy dispersive spectroscopy, and total metals analysis, are expected to be piloted as potential alternative sampling and test methods to the TCLP.

Deliverables

The deliverables from this project are expected to include:

- Biannual webcasts and interim status reports

- Meeting (virtual or in-person) with relevant stakeholders in PV, waste management, and regulatory communities

- Technical reports and presentations detailing the completed project tasks

- TCLP test results for modules contributed by project partners and funders

Price of Project

The price to participate is $32,500 per year for two years ($65,000 total). This project is eligible for self-directed funds (SDF) or co-funding.

Project Status and Schedule

The project is expected to take two years to complete. A limited scope can begin with at least two funders, and six or more participants are needed to complete the full desired project scope.

Who Should Join

This project may be of interest to utilities that own or operate solar PV facilities, and those with purchase power agreements from such facilities.

Others include anyone interested in understanding existing and future options for PV EOL processes and their environmental impacts.

Contact Information

For more information, contact the EPRI Customer Assistance Center at 800.313.3774 (askepri@epri.com).

Technical Contacts

Mitch Rencheck, Ph.D. at 865.292.3293 (mrencheck@epri.com)

Cara Libby at 650.776.6009 (clibby@epri.com)