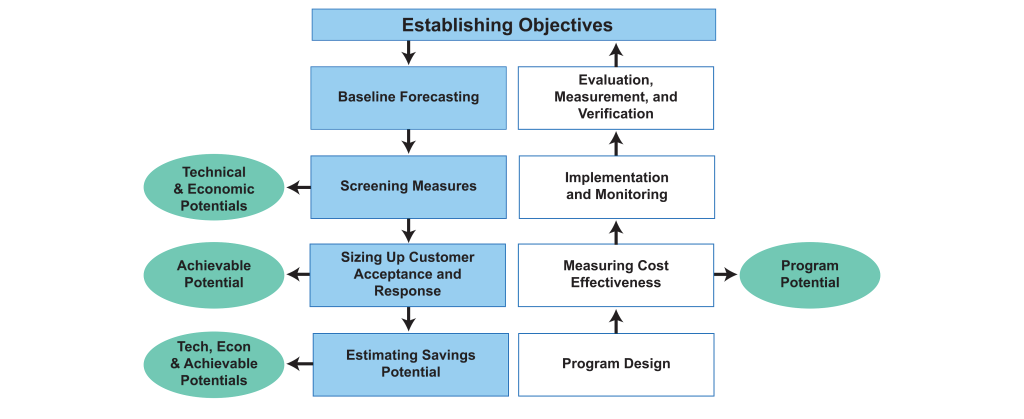

This study followed the analysis approach outlined in EPRI’s Energy Efficiency Planning Guidebook3 and depicted in Figure 1-1, which is consistent with the National Action Plan for Energy Efficiency (NAPEE) Guide for conducting Energy Efficiency Potential Studies4.

Figure 1‑1. General Energy Efficiency Analysis Framework

Defining Potential

One of the primary objectives of this study is to develop several estimates of the energy efficiency potential across regions and end-uses. Depending on the screening criteria used, several different potentials may be defined. The approach for deriving achievable potential is based on first establishing both a technical potential and an economic potential, and then discounting these estimates to reflect market and programmatic constraints.

This study uses a stock turnover model to estimate the number of end-use devices in the market, and assumes that new equipment does not replace existing stock immediately or prematurely, but rather is “phased-in” over time as equipment reaches the end of its useful life. All of the categories of potential considered in this study are subject to this condition and may be considered “phase-in” potentials.5

Technical Potential

The technical potential refers to energy savings that would results if all homes and businesses adopted the most efficient, commercially available technologies and measures, regardless of cost. As in all cases, replacement is assumed to occur at the end of the useful life of the existing equipment, yet the technical potential does not consider cost-effectiveness nor any market barriers to adoption of the efficient equipment or measures.

Economic Potential

The economic potential represents the electricity savings from programs that would result if all homes and businesses adopted technologies that pass a standard benefit-cost test. Economic potential does not consider market barriers to technology adoption.

In this case, the Total Resource Cost (TRC) cost test is used, which uses information on the costs and energy consumption profile of a measure compared to baseline technology to calculate its cost-effectiveness over its life6. The TRC compares the present worth of the avoided power supply costs to the incremental measure cost plus the administration cost of the energy efficiency program (assumed to be 20% of incremental measure cost in this case)7. If several measures pass the benefit-cost test (with value greater than 1.0), the measure with the greatest energy savings is adopted.

The TRC test does not consider any incentives given to promote technology adoption. These incentives would be considered a cost to the utility and a benefit to the participant, and would net to zero in the overall cost-benefit calculation. As a result, TRC scores do not depend on incentives provided.

Achievable Potential

After calculating technical and economic savings potentials, additional factors are applied to represent a forecast of likely consumer adoption. While a range of market barriers and adoption factors can be considered, the primary driver of technology adoption is generally the cost-effectiveness of the technology to the end-user. To estimate how much of the economic potential is realistically attainable, an achievable potential estimate is estimated for each end use. For each end use and building type, the levelized cost of energy (LCOE) is compared to the retail rate for electricity in each state to estimate the cost-effectiveness of the technology to the customer. For technologies with LCOE lower than the average retail rate, customer adoption is more aggressive.

Energy-Efficiency Measures under Consideration

The analysis of potential savings from utility programs begins with a list of energy efficiency measures. This list includes high-efficiency appliances and equipment for most end uses, many of which have numerous efficiency levels, devices, controls, maintenance actions, and enabling technologies. Table 1-1 and Table 1-2 list the categories of energy-efficiency measures that are included in the analysis of energy use in the residential and commercial sectors. Rather than consider individual measures, energy savings in the industrial sector are applied to the industrial processes within each manufacturing segment in a top-down manner

Table 1-1 Categories of Residential Efficiency Measures Considered

Table 1-2 Categories of Commercial Efficiency Measures Considered

All of the measures listed in Table 1-1 and Table 1-2 are considered when estimating technical potential, as described earlier. Yet only the subset of measures that passes the economic screen is included in the economic and achievable potentials.

Model Enhancements for 2018

Several updates and enhancements were made in this revision of the study to better reflect current markets conditions and more accurately characterize savings potential. These updates include enhancements to the underlying model structure—shown in Table 1-3—as well as updates to the input data and assumptions used in the model—shown in Table 1-4.

Table 1-3 Structural Changes to the Model

Structural Changes

- Added distribution capacity costs to avoided utility costs

- Greater sub-regional specificity: split out NY

- Updated stock turnover model, including survivor curve

- More robust treatment of bundled (secondary) measures and attribution of savings

- Updated approach to modelling new technology adoption

- Updated treatment of lighting to reflect modern technologies

- Considered historical performance of utility programs

Table 1-4 Structural Changes to the Model

Updated Input Data

- Baselines updated to AEO2018

- Incorporation of current codes and standards

- Updated utility cost planning; reserve margins, energy and demand losses, summer/winter allocations

- Updated costs and impacts of technologies

The first and perhaps most significant update is to the avoided costs used for calculating measure economics, here using the TRC test. These costs represent the average cost to deliver service to a device, including generation, transmission, and distribution, and considering load profile (i.e. timing of demand). Over the last five years, changes in the generation resource mix across the United States have dramatically altered the avoided cost of energy.

For the first time, this study includes the avoided cost of distribution capacity in the economic screening. Feedback from EPRI’s October 2017 stakeholder workshop in Washington, D.C.8 indicated that both transmission and distribution capacity costs should be included to best reflect long-run marginal costs. Collected from several recent studies, these costs show that the avoided transmission and distribution are significant contributors in the cost-effectiveness of efficiency programs, particularly in high-cost regions such as New York and California.

The second major update includes how the impacts of combinations of efficient measures are considered. When multiple efficient measures are considered—for example upgrading insulation and HVAC equipment simultaneously to save on space cooling—the combined effect (on space cooling energy consumption in the example) is not simply the sum of individual savings contributions. Without considering the compound impact of each added measure, the overall energy savings of multiple measures in a single end-use category may be over stated. EPRI’s treatment of secondary measures was revised to better reflect the energy savings and cost-effectiveness of efficient measures in concert. This updated approach is expected to reduce the overall savings potential of compound measures compared to previous studies, particularly in residential HVAC and water heating.

Finally, the fundamental structure of the model was rebuilt to allow greater flexibility in making future updates and enhancements. While this has limited impact on the results of this study, it allows future efforts to be more easily updated and tailored for specific objectives, as needed (for example, to examine impacts for a specific state and/or region in greater detail).

3 Energy Efficiency Planning Guidebook. EPRI, Palo Alto, CA: 2008. 1016273.

4 P. Mosenthal and J. Loiter, “Guide for Conducting Energy Efficiency Potential Studies,” U.S. EPA, Arlington, VA, 2007.

5 In other words, no “mid-life” replacements of existing equipment for more efficient equipment are assumed, even though such replacements may be economically justifiable in some cases. Such actions can be considered as market-driven or “naturally occurring” savings if they would occur independent of an energy efficiency program.

6 California Public Utilities Commission. California Standard Practice Manual: Economic Analysis of Demand-Side Programs and Projects. Sacramento, CA: October 2001.

7 TRC is an industry standard metric defined in the California Standard Practice Manual to calculate the overall benefit-cost ratio of a technology’s adoption. TRC considers the costs to the utility, program participants and non-participants, including avoided supply costs, equipment installation costs, and costs to administer the program, providing the perspective of all ratepayers. While TRC calculates the cost-effectiveness of a program to promote technology adoption, it should not be confused with the cost-effectiveness to the customer of the adoption of a technology.

8 EPRI’s Energy Efficiency Potential Workshop. EPRI, Palo Alto, CA: 2017. 3002012190.