Background

AES Eletropaulo in Brazil required a new double-circuit 138-kV line between two 230-kV substations to provide an increased transfer capability between the stations and to provide service to three intermediate substations. One of the lines is being operated at 88 kV, even though it was designed for 138 kV. The 9.45-km long line would normally have been designed with a twin 636 MCM ACSR conductor bundle, with a capacity of 308 MVA at 88 kV and 483 KV at 138 kV.

Justification for the Selection of the Advanced Conductor

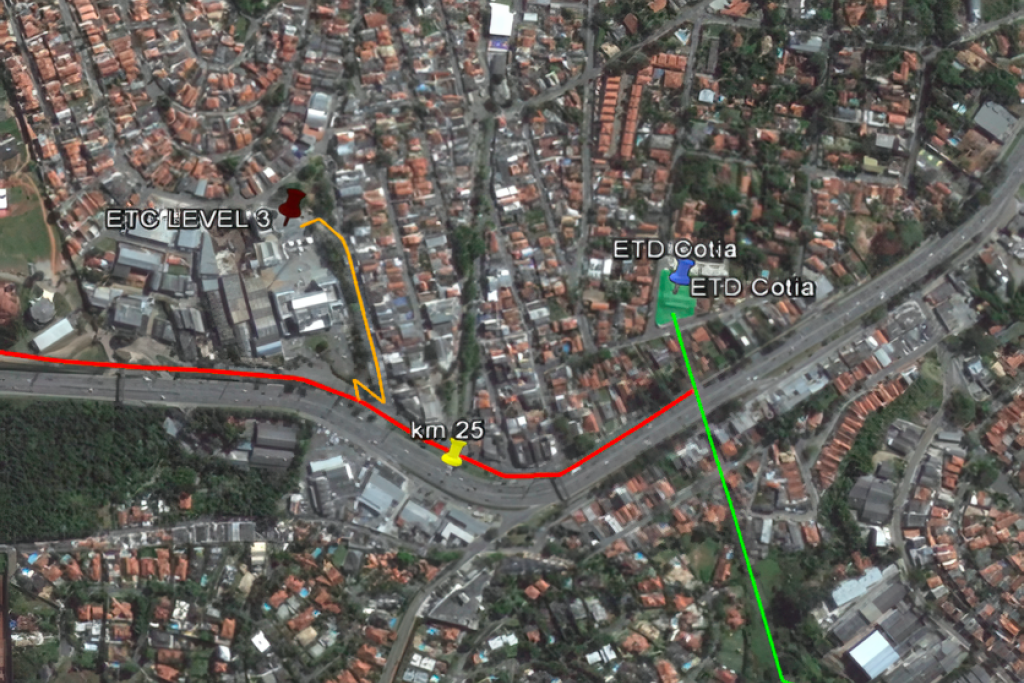

The line passes through two different areas. The first is a nonurban area where the typical steel lattice towers would be used. The second section was in a more urban area, where right of way and clearances are more restrictive (Figure 36). In the early planning stages, it was decided to use steel poles in the urban region. To minimize foundation costs, a conductor system was required, one that would develop minimal mechanical loading on the poles and the foundations yet match the same capacity as the bundle 636 MCM ACSR. The investigation of single-conductor options to minimize the mechanical loads resulted in HTLS conductors being evaluated as an alternative to meet the mechanical and electrical requirements. In Figure 36, the red line segment is the steel pole line to which the HTLS conductor will be applied. The orange section is the underground segment of the project. The green section is a traditional overhead line located in the area.

Figure 36. Urban area line route

After evaluating a few different HTLS options available, the final design chosen was based on the Nexans ACPR Lo-Sag 469/38-mm2 (section) conductor: (1) ACPR stands for thermal Aluminum Conductor Polymer matrix Reinforced—according to CIGRE WG B2.48; and (2) Lo-Sag nomination implies having Z-shaped wires. This conductor would be able to meet the 2000-amp capacity requirement and the mechanical load requirements, as well as maintain desired clearances. The final design was engineered for the typical 636 bundle and lattice towers in the non-urban area and the new design using steel poles and a single T-rail conductor (Figure 37).

Figure 37. Monopole with low-sag conductors installed

Installation Comments

The installation of the HTLS conductor was done in a similar manner to that used for ACSR conductors. Specific training sessions were held by Nexans for the crews, focusing on the installation of the dead-ends and other accessories.