ACCR

Bonneville Power Administration

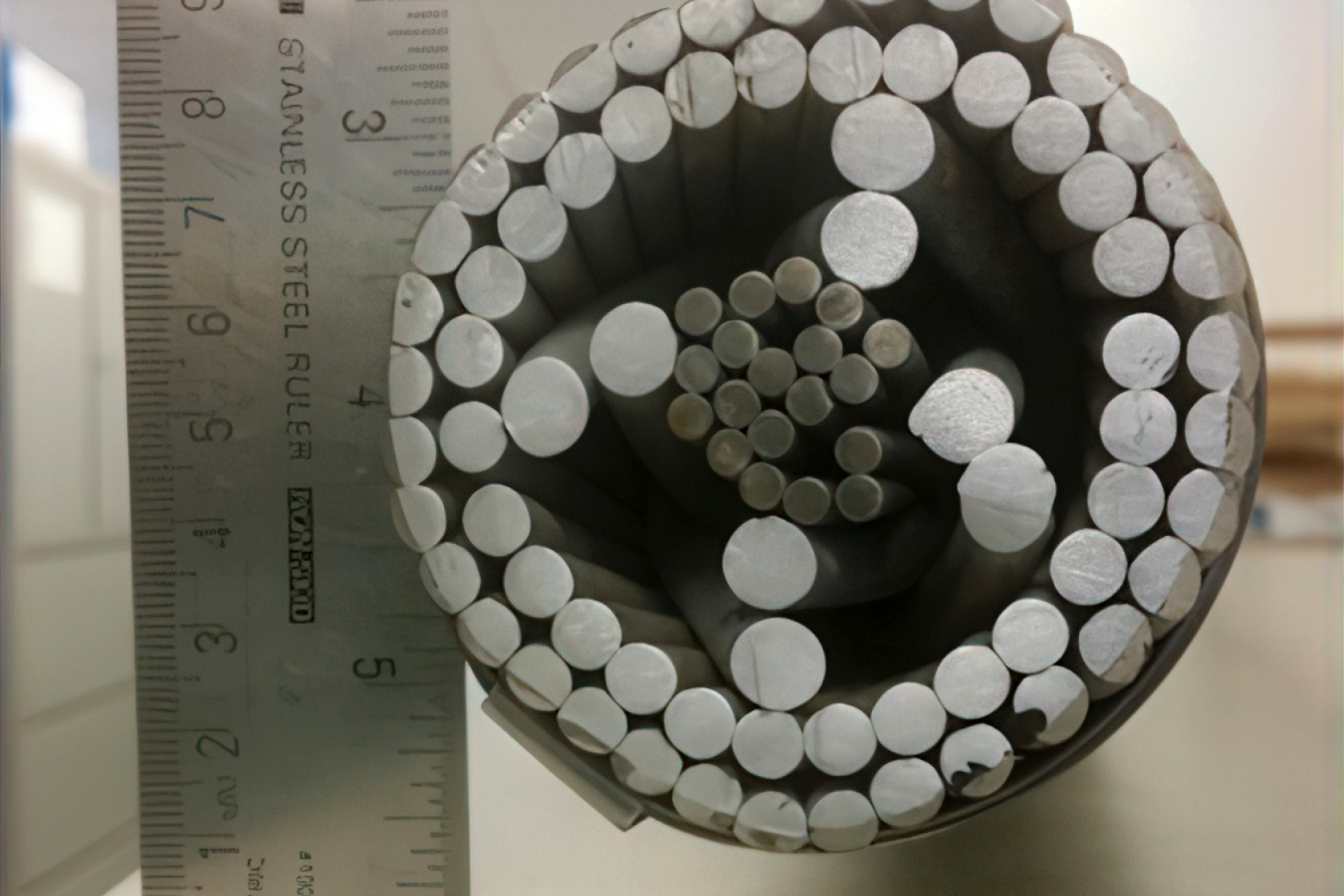

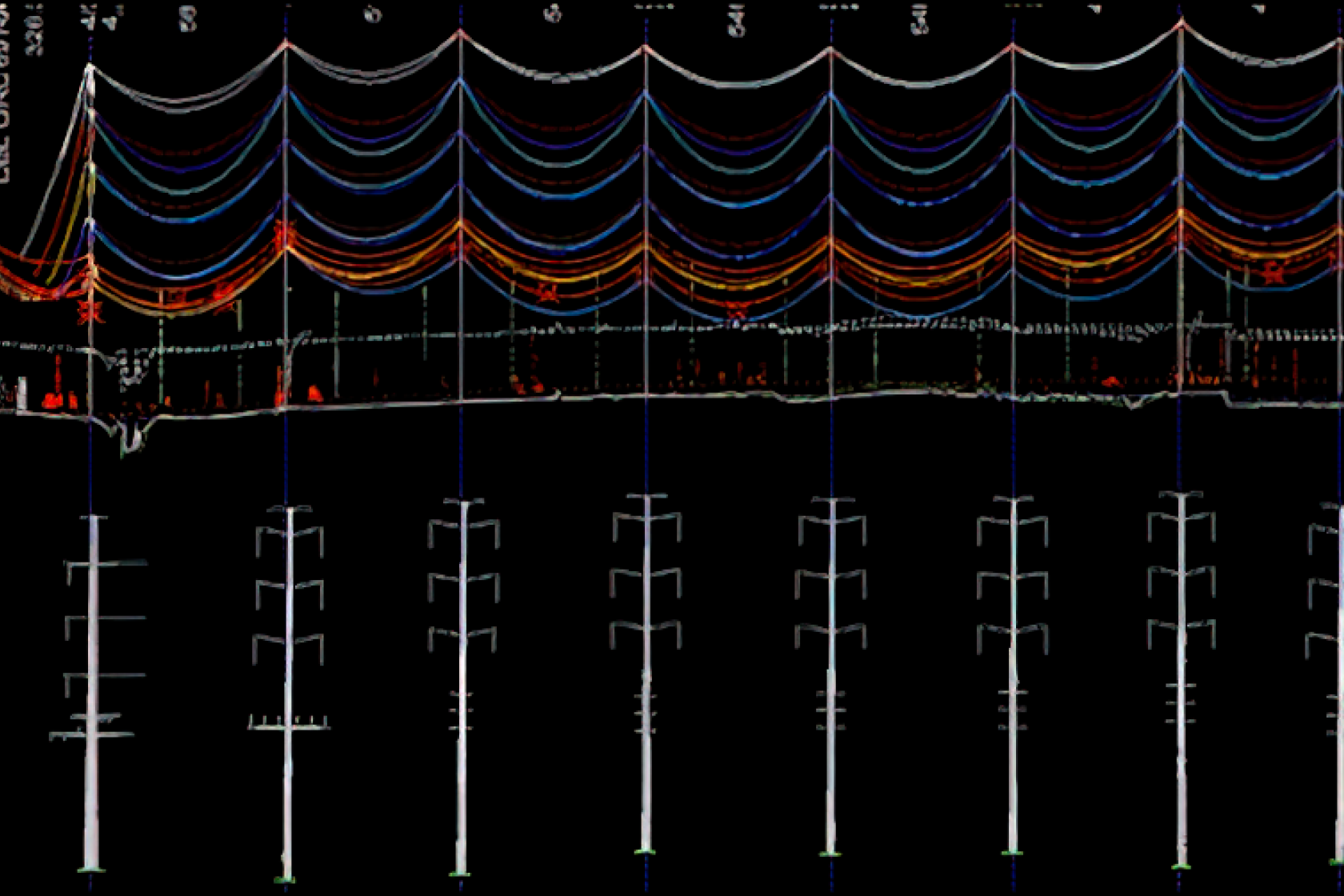

BPA has been systematically replacing 2.5-in. (64-mm) expanded conductors from its system over the past decade. The 2.5-in. (64-mm) expanded conductor was used as a single conductor for 500-kV circuits starting in the 1960s. It was designed along with a series of towers to be an extremely efficient system.

Southern Company

Advanced conductors have solved problems for several Southern Company transmission projects that had numerous access difficulties, tight schedules, and underbuilt joint facility construction. Two specific projects involved a 16.7-mi (26.9-km) -long, 230-kV line requiring a 2500-amp capacity. The line occupied one side of a double-circuit tower line through both industrial and rural, as well as residential, areas.

Western Area Power Administration

An N-2 outage is a multiple contingency event in which two elements of the grid fail, such as two transformers, generators, or transmission lines. Power flow studies have shown that a credible N-2 outage of both Shasta-Cottonwood 230-kV transmission lines would result in an overload of the Shasta-Keswick 230-kV transmission line.

Arkansas Electric Cooperative Corporation

In 1963, Arkansas Electric Cooperative Corporation (AECC) completed the Thomas B. Fitzhugh Generating Station at Ozark. At the time, the plant—the first built by a co-op in Arkansas—provided 50 MW of natural gas- and oil-based electricity generation.

In 2003, the plant was expanded to 171 MW. Eventually, this led to the need to upgrade transmission lines delivering power from the plant to users, including the 161-kV Fitzhugh-SPA (Southwestern Power Administration) line.

Entergy

As part of the plan to deactivate the Michoud generating facility, Entergy New Orleans, LLC, determined that two leads from the Ninemile generation facility needed upgrading. The Ninemile to Napoleon 230-kV line feeding the warehouse and central business district of New Orleans and the Ninemile to Derbigny 230-kV line serving the New Orleans Superdome and adjacent area of the city required increased capacity. These two lines are entirely enveloped in the urban confines of New Orleans plus a crossing of the Mississippi River and four Interstate 10 crossings.

Lower Colorado River Authority

Lower Colorado River Authority (LCRA) needed to upgrade the capacity of a dual-circuit, 138-kV lattice tower transmission line. The line was one of the oldest on the LCRA system, built in the late 1930s, using 203.2 ACSR Brahma, and was previously reconductored in 1987 with a 795 ACSR Condor. The upgrade presented several challenges.

ACSS and ACCC

CenterPoint Energy

ACSS

CenterPoint has long used ACSS conductors for new and upgrade projects across their system. An expansion in generation required that the construction of a 2800-MVA, 345-kV line be built on an existing transmission tower line and partially on a new right of way. CNP believed that the existing ACSS conductors available did not quite fit the needs of the project and looked toward the recently developed extension of ACSS capabilities by Southwire with a new core strand coating that withstood higher operating temperatures and a UHS steel core strand.

American Electric Power

ACCC

AEP has made several applications of advanced conductors over the past 10 years, for 138–345 kV. These projects have predominantly been involved in increasing capacity into existing load areas. Upgrade alternatives were limited, constrained by urban growth and the inability to secure additional rights of way for new lines. Reconductoring lines on existing corridors primarily focus on whether the existing structures can support the new conductor(s) required for the target capacity and whether the structure heights with the new conductor provide adequate clearance.

Cheyenne Light, Fuel, and Power Transmission

ACCC with E3X

In 2013, Cheyenne Light, Fuel and Power Transmission constructed a new 115-kV line on the outskirts of Cheyenne, WY, to serve a growing part of town. The initial installation was a double-circuit, 115-kV steel monopole construction using 795-kcmil ACSR Tern rated at 953 amps. After installation was complete, one circuit saw a large, unexpected load increase due to a growing end user. By 2018, this circuit was reaching capacity so methods to increase capacity while preserving the existing structures were evaluated and a decision was made to reconductor.

Nevada Power

ACCC

In 2009, Nevada Power (doing business as NV Energy) identified a 220-kV transmission line that required an increase in transfer capacity from its current 300 amps using a 2/0 Cu conductor to a minimum of 1000 amps. Traditionally, NV would use a 954 ACSR conductor for this line capacity level, but the wood H-frame line built in 1952 could not support the increased mechanical loading of a 954 ACSR conductor. The typical upgrade would require a complete rebuild of the 13-mi (21-km) -long line.

Cross Timbers

ACSS and ACCR

In the mid-2000s, the Public Utility Commission of Texas, along with the Electric Reliability Council of Texas (ERCOT), coordinated an extensive construction program of transmission lines to support the expansion of renewable wind energy sources in western Texas, referred to as the Competitive Renewable Energy Zones (CREZ).

Southern California Edison

ACCC

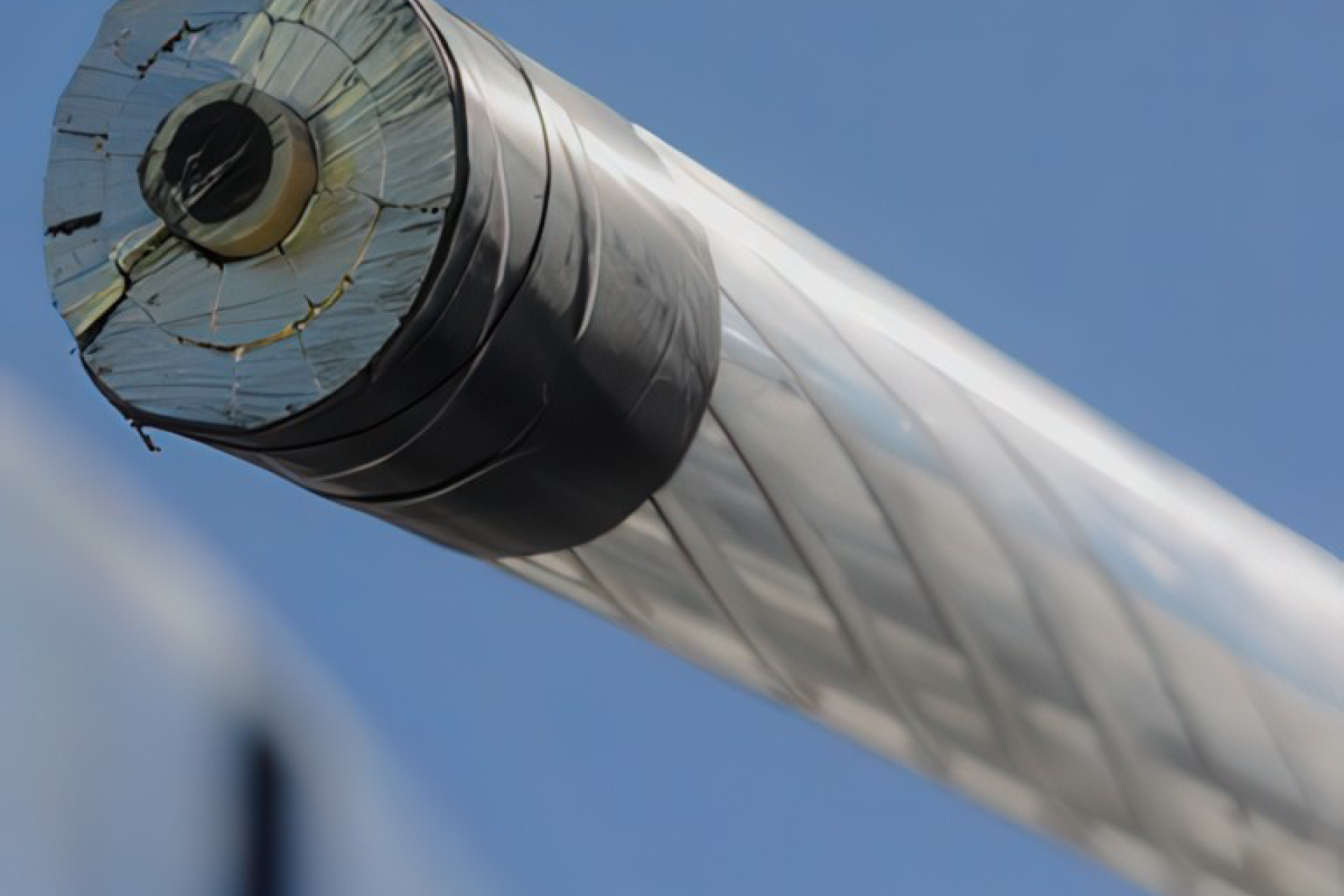

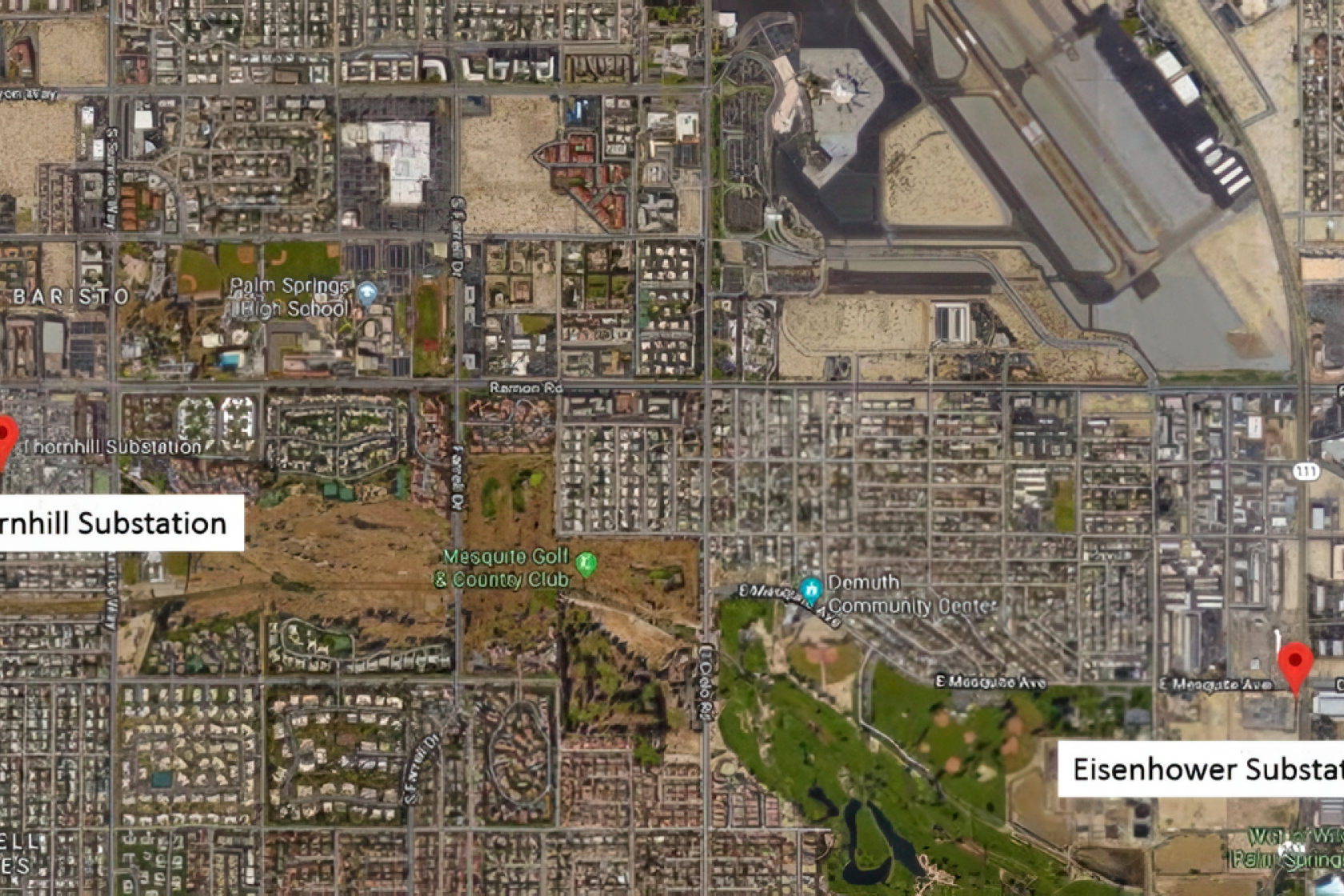

SCE was faced with a project with several constraints. Moderate load growth combined with existing thermal sag limitations required a twofold solution to upgrade a transmission line: first, eliminating thermal sag restrictions on many of the spans with aged ACSR and some lines with ACSS conductor and, second, retaining the existing structures to avoid the need to get additional approval. The existing line connecting the Eisenhower and Thornhill substations near the Palm Springs Airport (Figure 30) is in congested commercial and residential areas.

Avista

ACSS with E3X

Avista utilities identified a need for increased capacity in the area around Spokane, Washington. Load growth and the need to provide access to a more diversified mix of generation lead to potential overloads on a 70-year-old 115-kV line. Avista has been carrying out a progressive enhancement and upgrading program across their infrastructure with numerous environmental, regulatory, financial, and landowner constraints driving broader solution evaluations and engineering decisions.

Arizona Public Service

ACCS

Based on forecasted load growth and planned reliability improvements, Arizona Public Service (APS) identified the need for a new 69-kV line connecting the Cactus and Altadena substations in Scottsdale, Arizona. APS worked through a line-siting process, which included many avenues of input, including meetings and comments from the local community.

Tenaga Nasional Berhad (Malaysia)

ACCC

In Johor Bahru, Malaysia, a joint venture developing a petrochemical and power generation site using Cogen Technologies needed to build a transmission line connection to the Peninsular Malaysia Grid. Tenaga Nasional Berhad and Petronas required a double-circuit, 275-kV line of 50 km in length to serve as the interconnection. The capacity requirement was 2151 amps per circuit.

Other

AES Electropaulo (Brazil)

ACPR

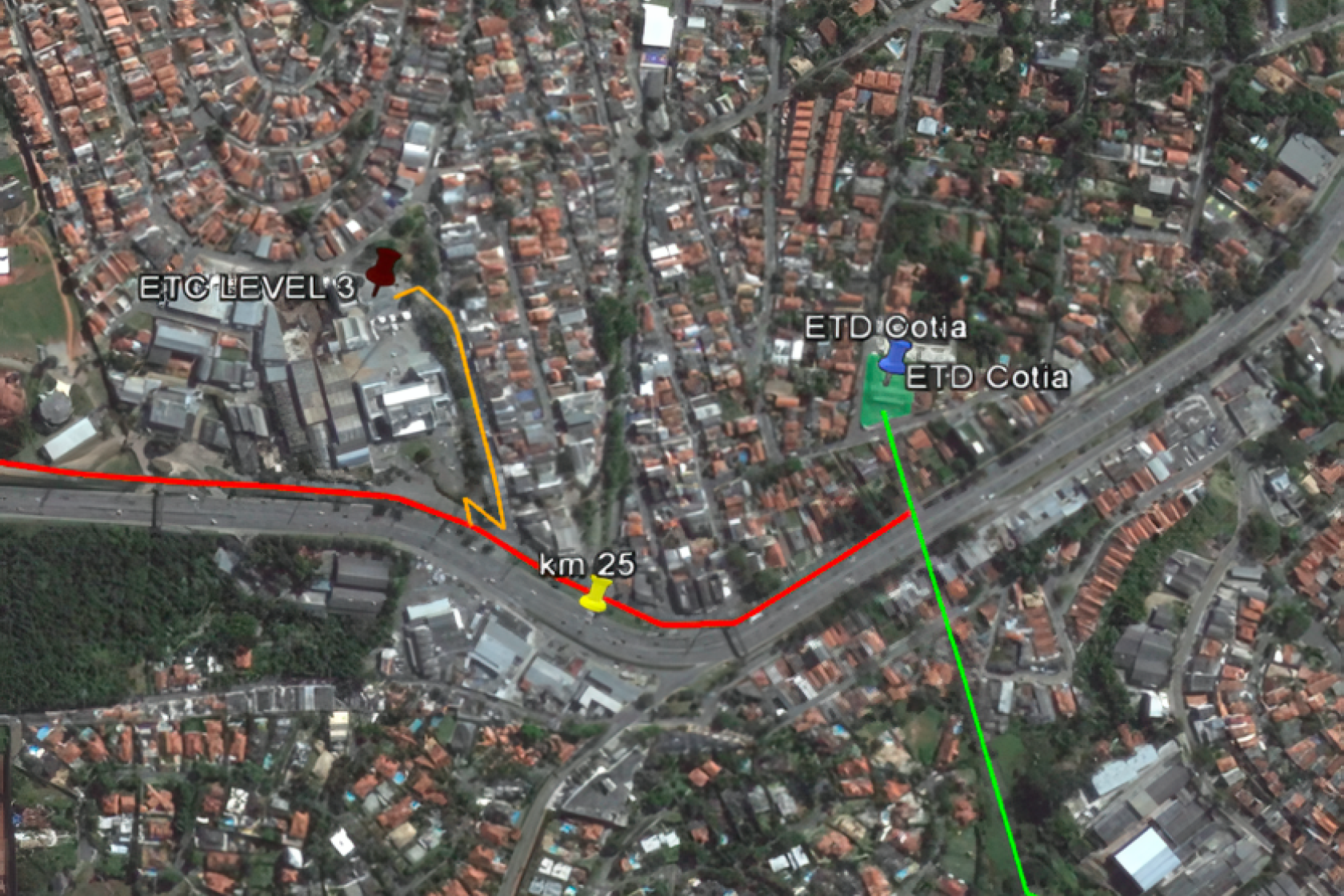

AES Eletropaulo in Brazil required a new double-circuit 138-kV line between two 230-kV substations to provide an increased transfer capability between the stations and to provide service to three intermediate substations. One of the lines is being operated at 88 kV, even though it was designed for 138 kV. The 9.45-km long line would normally have been designed with a twin 636 MCM ACSR conductor bundle, with a capacity of 308 MVA at 88 kV and 483 KV at 138 kV.

ELIA (Belgium)

LO-SAG

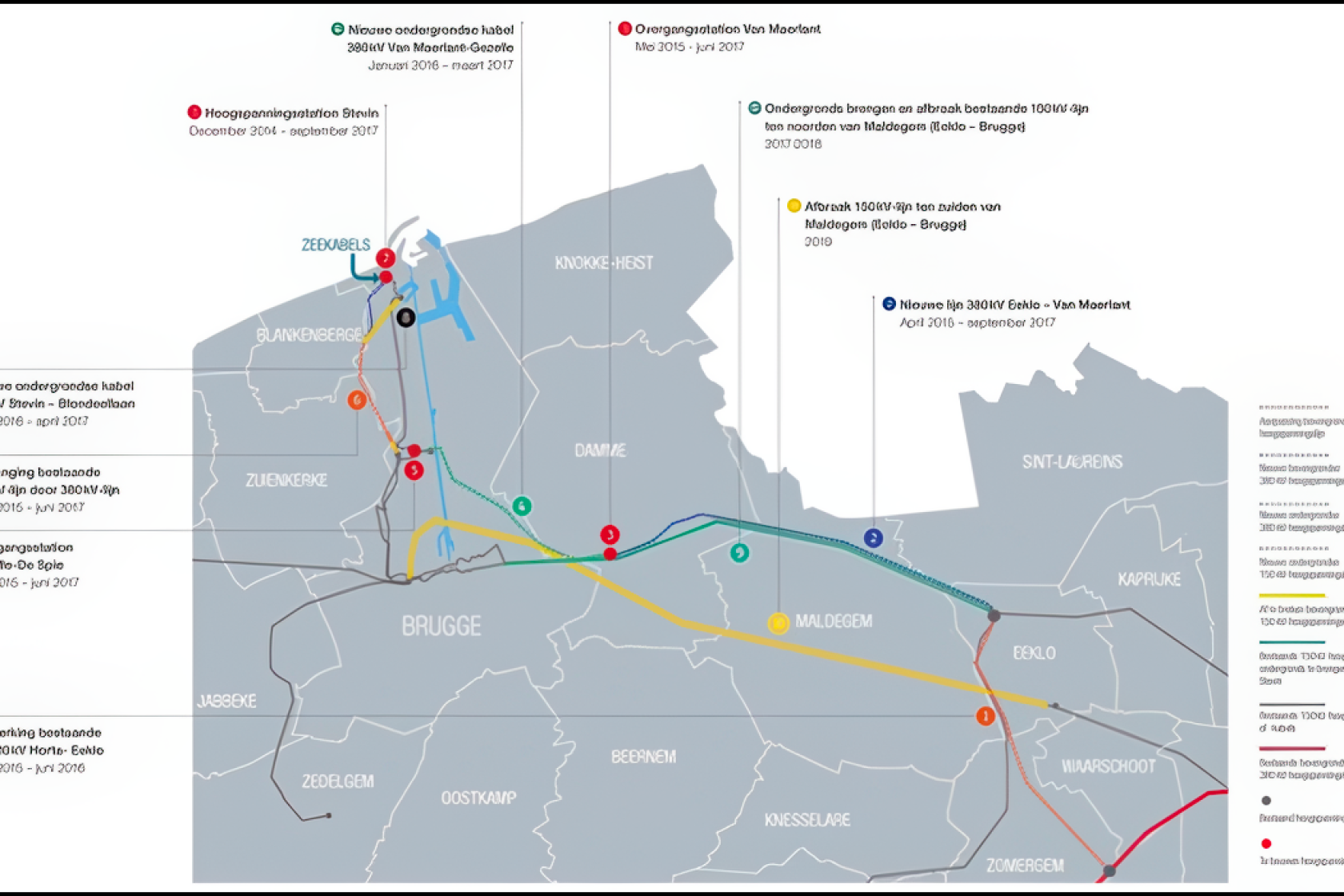

The current 150-kV grid in the coastal region of Belgium needs to be upgraded to meet future energy needs. The Stevin project, a new 380-kV connection between the coast and the existing 380-kV backbone grid, is aimed at addressing this issue. Figure 38 shows the line route.

Northern Ireland Electricity

GAP-TYPE

Northern Ireland Electricity (NIE) needed to increase the capacity of a double-circuit, 110-kV line in Northern Ireland without building a new line into the area or upgrading the existing line without significant or any structural modifications.

City Power Johannesburg (South Africa)

HVCRC

The design capacity of the existing transmission lines varied between 60 and 100 MVA. Due to local constraints, new rights of way and new transmission line construction were not possible. City Power’s plan identified key network upgrade projects that had to be carried out to avoid network overloading.

TIWAG-NETZ AG (Austria)

ZTACIR

In a paper presented to CIGRÉ General Conference in 2012, TIWAG-Netz AG discussed its development of a reconductoring project using the ZTACIR conductor. An 85-km-long 220-kV line (over 50 years old) across the Alps had been experiencing several maintenance and reliability issues (inability to maintain N-1 criterion and excursions above the conductor’s thermal limit).

State Grid NINGXIA (China)

TS

State Grid Ningxia is in the plateau of the northwestern part of China, where strong winds (27 m/s, 60 mph), ice and cold weather (-30°C), combined with desert heat (40°C) must be considered for the design of transmission lines.

CEMIG (Brazil)

ACFR, GZTACSR, AND ACCC

CEMIG in Brazil tested several HTLS conductors in an R&D project. The ACFR conductor was installed in the span between Towers 13 and 14 of the double-circuit, 138 kV between Neves 1 and Neves 2 substations, in August 2019. The original configuration of the line has single 170,6 MCM ACSR Linnet conductors providing capacities of 150 MVA at 138 kV. The line length is approximately 13.97 km.