Background

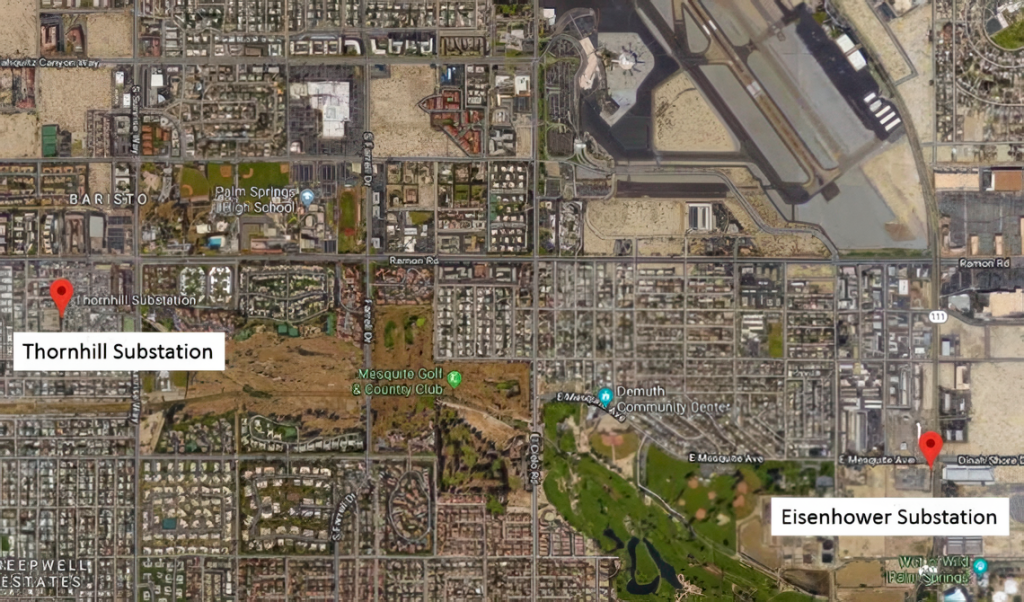

Southern California Edison (SCE) was faced with a project with several constraints. Moderate load growth combined with existing thermal sag limitations required a twofold solution to upgrade a transmission line: first, eliminating thermal sag restrictions on many of the spans with aged ACSR and some lines with ACSS conductor and, second, retaining the existing structures to avoid the need to get additional approval. The existing line connecting the Eisenhower and Thornhill substations near the Palm Springs Airport (Figure 30) is in congested commercial and residential areas.

Figure 30. Aerial view of SCE Eisenhower and Thornhill, 115-kV line

Options Considered

SCE investigated several conductor types and sizes in its reconductoring study. As noted previously, the utility wanted to avoid the need for a certificate or necessity, which would be required if the existing structures had to be replaced or significantly strengthened. The conductor study was constrained to find a conductor type and size that provided the desired capacity, including a modest increase for area load growth, yet mitigated the need to replace, heighten, or reinforce the structures. The solution needed optimum sag performance without increases in tension at angle structures and nominal physical characteristics—for example, diameter for wind loading management and weight to avoid arm overloading. The ACCC conductor uses lighter weight composite core and trapezoidal shaped strands, which allow the incorporation of 28% more aluminum without a weight or diameter penalty.

The SCE reconductoring project not only mitigated sag issues while enabling some future load growth, but also the project was completed quickly and economically with virtually no environmental impact, because an ACCC conductor enabled the use of the existing structures with no modification or need for structural replacement. The 115-kV reconductoring project used a 530-kcmil Laredo size ACCC conductor manufactured by CTC Global and General Cable.

Installation Overview

CTC Global provided training to 13 SCE crew members and remained on site to help as needed. Even though the area is well developed, care was still taken to avoid harming any of the local residents, including the Coachella Valley fringe-toed lizards and flat-tailed horned lizards and the Palm Springs round-tailed ground squirrels. The project was completed under a maintenance permit and went very smoothly with SCE’s outstanding crew.

SCE’s upgraded line offers greater capacity, improved reliability, and fire safety due to its high strength and low-sag composite core. The ACCC conductor’s increased aluminum content (without a weight or diameter penalty) also serves to reduce electrical line losses by an estimated 30%. Reduced line losses not only reduce fuel consumption and associated emissions, but also free up generation capacity that is otherwise wasted.