Background

Advanced conductors have solved problems for several Southern Company transmission projects that had numerous access difficulties, tight schedules, and underbuilt joint facility construction. Two specific projects involved a 16.7-mi (26.9-km) -long, 230-kV line requiring 2500-amp capacity. The line occupied one side of a double-circuit tower line through both industrial and rural, as well as residential, areas (Figure 4).

Figure 4. A 230-kV corridor approaching a substation

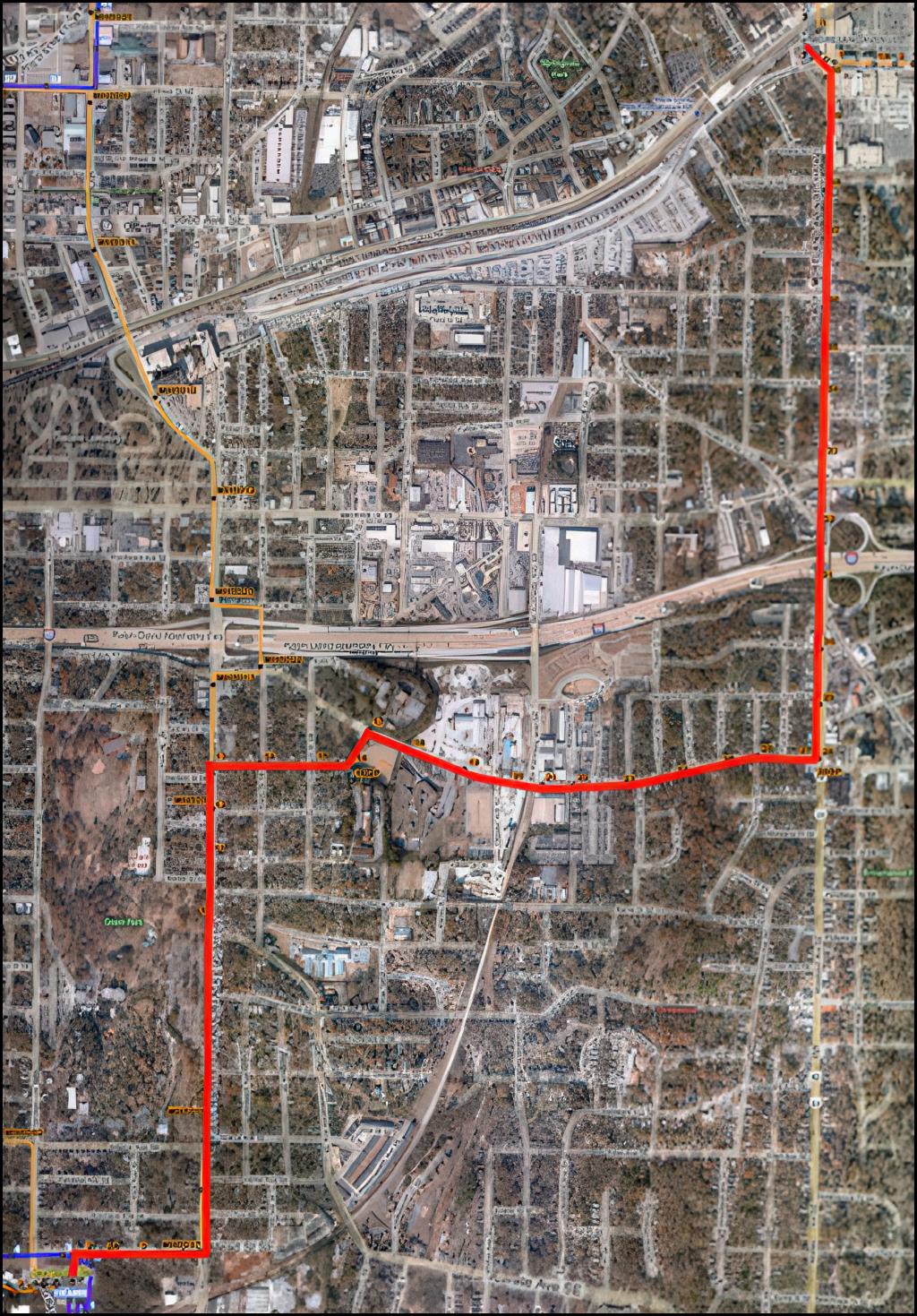

The second project involved upgrading a single-circuit, 115-kV line that was 3.5 mi (5.6 km) long and required 1500-amp capacity. This line was in an urban area along streets in highway easements on steel poles supporting numerous joint-use attachments (Figure 5 and Figure 6).

Figure 5. A 115-kV corridor along urban streets

Figure 6. Sample line location—street easement and joint occupation

Securing new easements or additional space was not a practical option for either of these projects. Inspections of the structures showed them to be in good condition, so reconductoring appeared to be the best option for solutions. An appropriate conductor type and size were required that would deliver the desired capacity and minimize issues with the structures regarding the structural ability to carry the mechanical loads and provide adequate clearance to maintain safety.

Options Evaluated

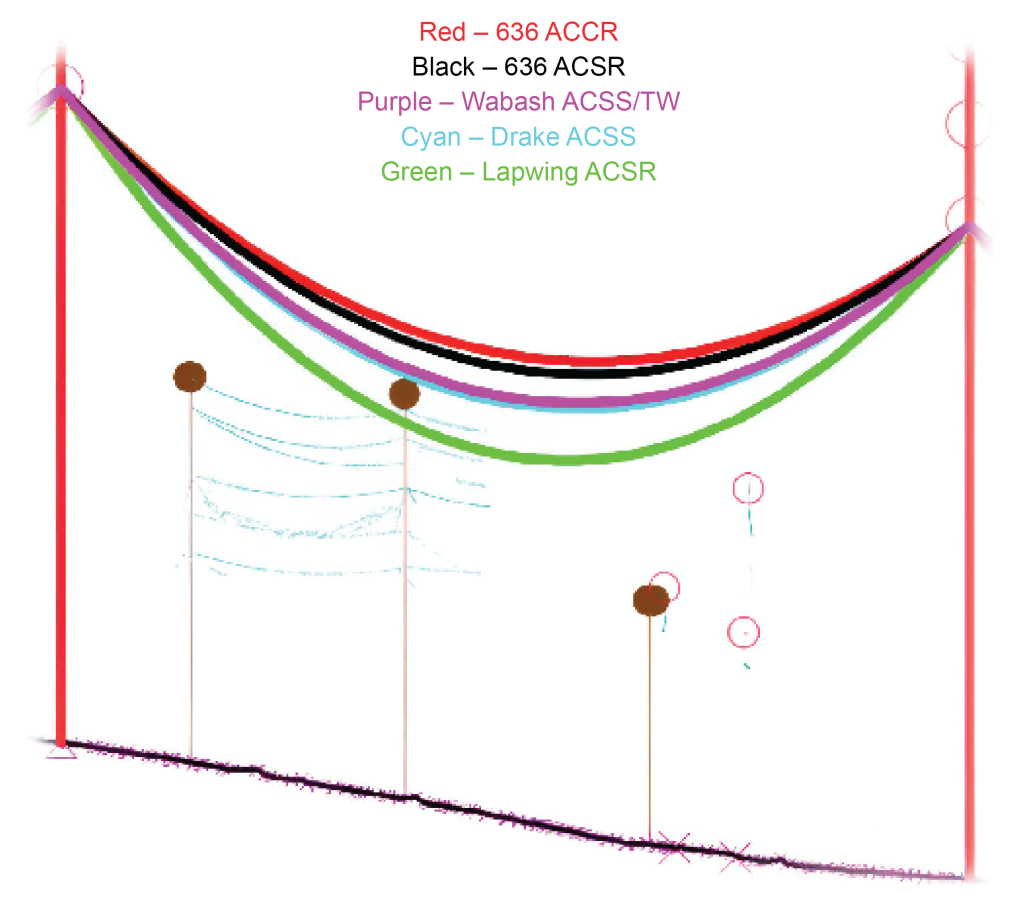

For the 115-kV option, the conductors in Table 2 were evaluated based on structure loadings and maintaining clearances (Figure 7). The ACSR alternative had significant loading increases, which would require structure modifications or a replacement, neither of which was a practical solution to this particular right of way. The sag plots indicated that the ACCR had the best clearance opportunity.

Table 2. A 115-kV line alternative for conductor solutions

| Name | Diameter (in.) | Wt/ft (lb/ft) | Rating (amps) | |

|---|---|---|---|---|

| Existing Conductor | ||||

| 636 ACSR 26/7 | Grosbeak | 0.99 | 0.8742 | 907 at 100°C |

| Alternatives | ||||

| 1590 ACSR 45/7 | Lapwing | 1.504 | 1.7903 | 1586 at 100°C |

| 795 ACSS 26/7 | Drake | 1.108 | 1.0934 | 1611 at 200°C |

| 762.8 ACSS/TW T-16 | Wabash | 0.99 | 1.046 | 1573 at 200°C |

| 636 ACCR 26/19 | Grosbeak | 1.006 | 0.74 | 1562 at 240°C |

1 in. = 25.4 mm; 1 lb/ft = 1.49 kg/m

Figure 7. A 115-kV alternative solution for clearance comparison

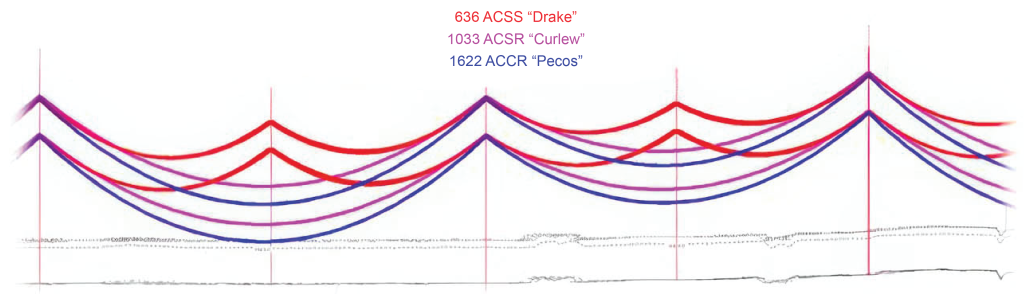

The 230-kV project had a different set of constraints. The line of interest was a circuit on one side of a double-circuit tower, so the option of structural modifications was not feasible.

Table 3 displays some of the alternative conductors studied, and Figure 8 illustrates comparative clearances for some conductors.

Table 3. A 230-kV line alternative for conductor solutions

| Name | Diameter (in.) | Wt/ft (lb/ft) | Rating (amps) | |

|---|---|---|---|---|

| Existing Conductor | ||||

| 1 × 1033 ACSR | Curlew | 1.245 | 1.328 | 1231 at 100°C |

| Alternatives | ||||

| 1 × 1033 ACCR/TW | Curlew | 1.132 | 1.134 | 1885 at 210°C |

| 2 × 1033 ACSR | Curlew | 2.490 | 2.660 | 2462 at 100°C |

| 2 × 636 ACSS | Grosbeak | 2 × 1.006 | 1.48 | 2468 at 160°C |

| 1 × 1622 ACCR/TW | Pecos | 1.411 | 1.774 | 2537 at 210°C |

1 in. = 25.4 mm; 1 lb/ft = 1.49 kg/m

Figure 8. A 230-kV alternative solution for clearance review

From a structural loading aspect, the two ACCR options offer the least increase in loading on the structures. The ACSS and ACSR options needed bundles, requiring additional hardware assembly components and stringing costs on top of structural loading issues.

From a clearance perspective, the ACSS option required interspersing structures to gain the desired clearances. The Pecos option offered the best clearance option of the three.