Background

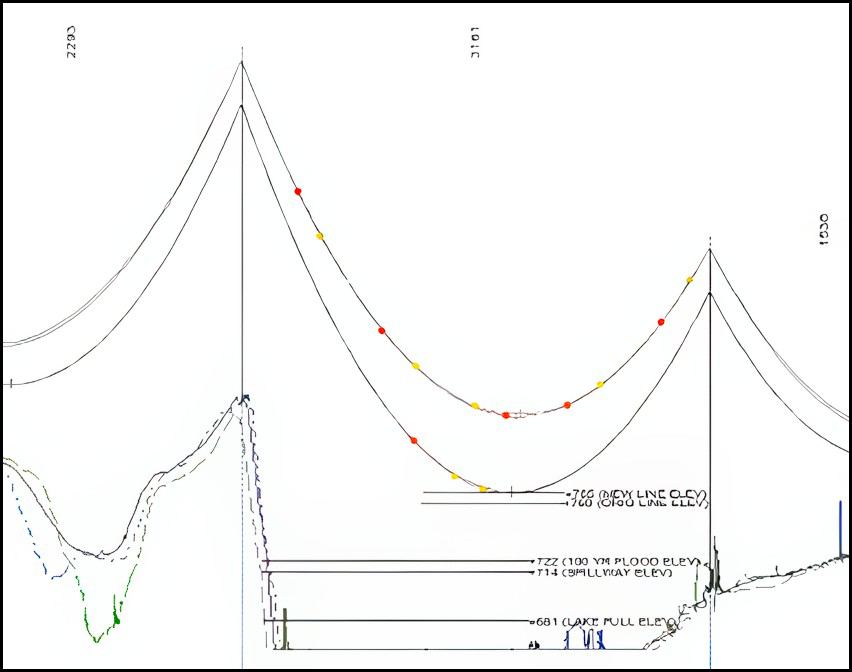

Lower Colorado River Authority (LCRA) needed to upgrade the capacity of a dual-circuit, 138-kV lattice tower transmission line. The line was one of the oldest on the LCRA system, built in the late 1930s, using 203.2 ACSR Brahma, and was previously reconductored in 1987 with a 795 ACSR Condor. The upgrade presented several challenges. The line has the longest and fourth longest spans on the system: 3161 ft (965 m) and 2293 ft (699 m). These spans are part of a long lake crossing, two suspension towers on each side of the lake, and spans on each side to anchor the towers. The lake crossing presented access challenges for tower modifications or replacements from a location standpoint, as well as growth around the line since it was originally built. One end of the span sits on a small bluff knoll, and the other is the ground base for a marina on the lake (Figure 17). There is no area for relocation of the towers, construction sites, or laydown areas. These towers are also lit according to Federal Aviation Administration (FAA) requirement, and it was desirable to avoid requiring any changes in the FAA permitting, based on previous issues with property owners in the area with respect to disco lighting complaints.

Figure 17. Lake crossing with a marina underneath

The latest upgrade was planned with a bundled 795 ACSR Drake. Most of the line was rebuilt with new structures, but LCRA wanted to use the existing four towers associated with the lake crossing. The tangent towers were modified during the 1987 upgrade to increase their height to 232 ft (71 m) from 150 ft (46 m). The towers were inspected and found to be in good condition. LCRA began an investigation for a conductor for the crossing that would allow retaining the towers with no or minimal modifications and appropriate sag-tension performance to maintain desired clearances.

Lake Travis was built as a flood control and potable water reservoir but also serves as a very busy recreational asset just west of Austin, Texas. The previously mentioned marina and boating life on the lake are used by sailboats as well as power craft. Many masts of the sailboats exceed the heights established in the NESC used to establish the minimum clearances required over navigable waters. LCRA established a minimum conductor elevation of 65 ft (20 m) above the maximum lake height (Figure 18). The bundled ACSR conductor planned for the line would not meet the requirements imposed by the lake crossing—that is, the mechanical loading on the structures and sag-tension performance to maintain desired clearances.

Figure 18. Lake crossing profile

Conductor Evaluation

LCRA decided to investigate the application of an advanced conductor as a solution. Initially, an ACSS conductor was found that met the capacity requirements and avoided tower modifications, but the sag-tension performance could not meet the sag restrictions required over the lake. Further consideration of advanced conductors introduced an evaluation of the sag-tension performance of the conductor with various ice loading considerations. Reviewing the sag performance for 0.5-, 0.75-, and 1.0-in. (12.7-, 19.1-, and 25.4-mm) radial ice, some sags exceeded those of the MOT. Although it is unlikely that sailing under the line would occur at maximum lake elevation and severe icing, LCRA decided to caution on the safe side and allow for the concurrent possibility and provide that clearance.

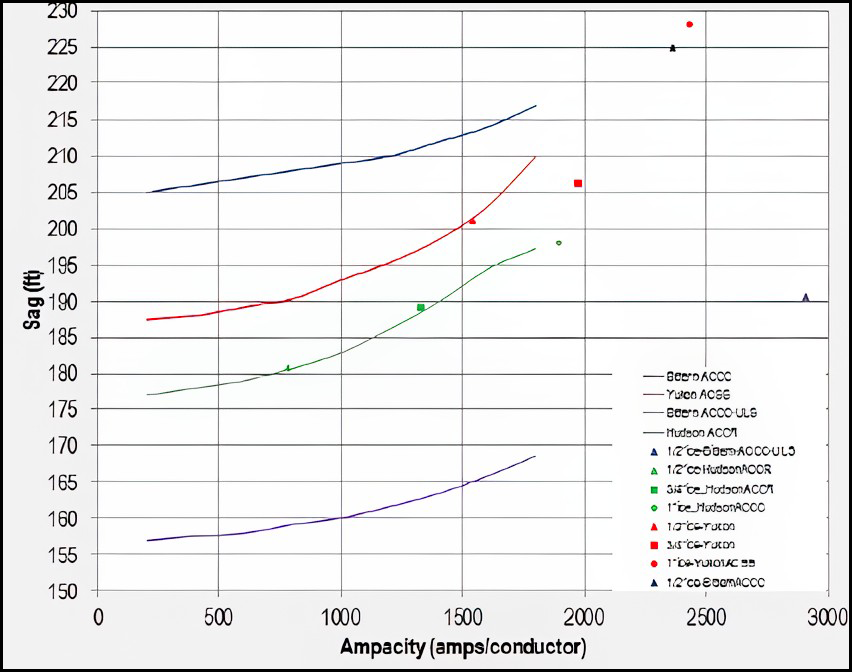

LCRA researched the performances of ACSS, ACCR, and ACCC conductors (Note: ACCC’s ultra-low sag conductor was not available at the time of the evaluation, though comparable results are shown). Figure 19 shows how the different conductors’ performances compared. The temperature clearances are plotted up to the desired MOT capacity. The sags associated with the ice loadings are plotted at their equivalent sag’s operating temperature. LCRA decided that it wanted to provide as much clearance as the MOT clearance with the different ice loadings.

Figure 19. Sag performance at MOT and ice loading

All the advanced conductors met the capacity requirement (~1866 amps) for sag limitation. The ice loading data, however, show that the ACCC and ACSS could not provide the desired ice-loaded clearances. The ACCC Bittern option also required a replacement of the tower arm hangers, which would have been very difficult with the existing conductor in place. The Hudson ACCR-TW solution was ultimately selected.

Construction

This was LCRA’s first application of ACCR; 3M was active with LCRA in securing appropriate conductor accessories to match the conductor and preparing the crews for installation. Several hardware mismatch issues arose between LCRA standard hardware assemblies and the material supplied by 3M. Lessons learned recommends fitting up all hardware prior to the field installation to avoid these issues.

Composite core conductors require a significantly larger bend radius of equipment to protect the core material. In this case, with the extra loads associated with the profile geometry of the spans, the stringing and suspension point bending radius required attention. During stringing,

the suspension points on the crossing spans had spreader beams with two large diameter blocks (Figure 20). This arrangement also made the attachment of the suspension assemblies easier because it provided support outside of the attachment area of the double-string assembly shown in Figure 21.

Figure 20. Spreader beam for stringing

Figure 21. Double suspension insulator assembly

Cost Comparison

Installation of an ACCR HTLS conductor was less than half the options that required a replacement of the two tall tangent lake crossing towers. In addition, eliminating tower modifications greatly reduced construction problems associated with access, property owner involvement, and permitting issues.