Background

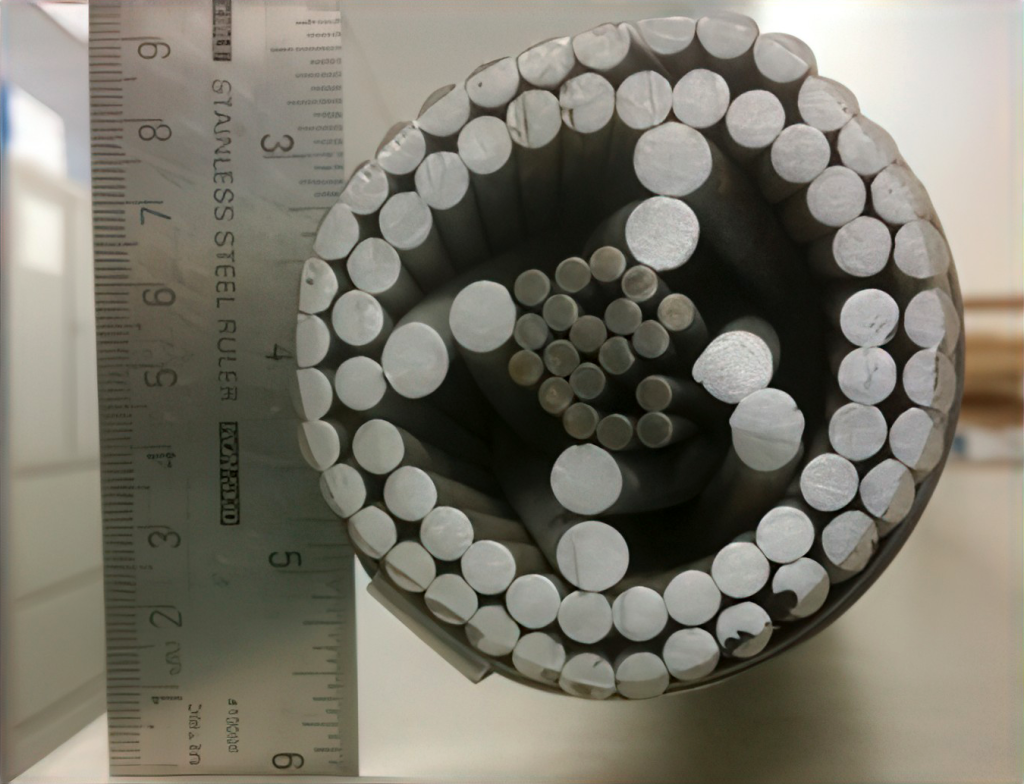

BPA has been systematically replacing 2.5-in. (64-mm) expanded conductors from its system over the past decade. The 2.5-in. (64-mm) expanded conductor was used as a single conductor for 500-kV circuits starting in the 1960s. It was designed along with a series of towers to be an extremely efficient system. The conductor is shown in Figure 1.

Figure 1. Cross-sectional view of the expanded conductor

Expanded conductor details are as follows:

- 3108 kcmil

- 92,000 lb (41,730 kg) RBS

- 3.91 lb/ft (5.82 kg/m) weight

- 2590-amp rating at 100°C

Benefits of using the expanded conductor design are as follows:

- Optimized loading (very high ampacity/load ratio)

- High strength—good for high ice, long spans, river crossings, and so on

- Single conductor—less hardware, labor for stringing

Challenges of using the expanded conductor are as follows:

- Big and heavy

- Very noisy—audible noise level

- Hard to find and maintain materials for maintenance (custom-designed conductor)

The standard replacement for the past decade has been the twin-bundle Chukar, ACSR. This has worked in 99% of cases, but there is a handful of river-crossing type spans where this results in too much tension for the towers to handle. A second alternative was needed to work alongside the twin-bundle Chukar on the long-span situations that do not require significant tower modifications. The twin-bundle Chukar is rated at 3500 amp at 100°C.

The following was the typical replacement conductor used:

- ACSR Chukar

- 1.6-in. (41-mm) diameter each

- 3560 thousand circular mils (kcmil)

- 3500-amp rating

- 102,000 lb (46,266 kg) RBS (total)

- 4.15 lb/ft (6.18 kg/m) (total)

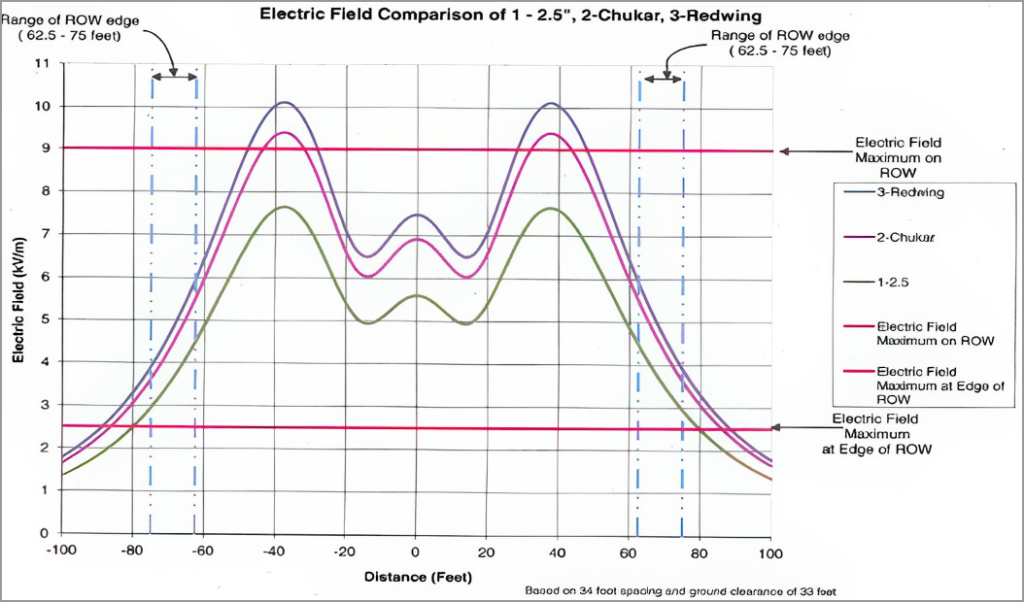

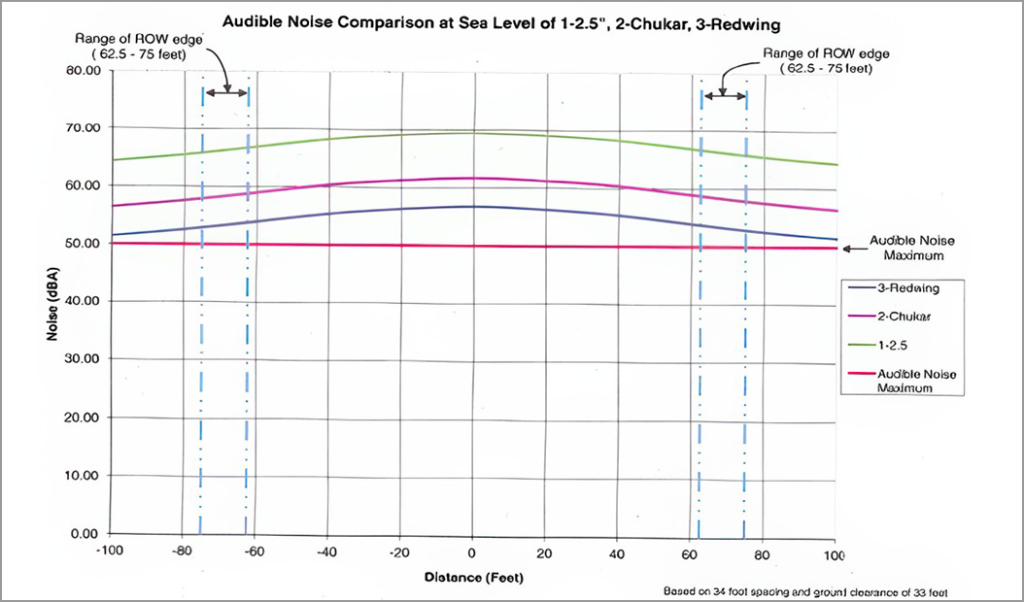

When evaluating potential bundles, twin and triple bundles were considered. It was determined that the minimum conductor size was 1.1 in. (28 mm) for twin bundle and 0.6 in. (15 mm) for triple bundle, based on electric field and audible noise guidelines. Using the NESC heavy load, which is typical on the BPA system, it was determined that the weather only load for a twin bundle would be 6.68 lb/ft (9.94 kg/m) and 7.94 lb/ft (11.82 kg/m) for a triple bundle. Because mechanical loading is a primary concern for this selection, a twin bundle was chosen.

A typical BPA 1.1-in. (28-mm) diameter conductor is ACSR/TW Rouge. It is rated individually at 1250 amp, resulting in a 2500-amp bundle rating at 100°C.

Challenges for the replacement conductor were that long spans and river crossings have too much tension and that switching to a conductor bundle would require tower modifications. Alternative conductors are required to meet these challenges. The replacement conductor would therefore need to meet the following requirements:

- Need to reduce loads for long-span applications

- ~10 locations

- Need to meet specific electrical effects limits. Electrical effects would govern the minimum conductor size in the bundle:

- Single bundle: N/A

- Double bundle: minimum 1.1 in. (28 mm) subconductor diameter

- Triple bundle: minimum 0.6 in. (15 mm) subconductor diameter

Figure 2 and Figure 3 show the electric field and audible noise limits as well as the simulated performance of some of the possible conductors.

Figure 2. Electric field profile

Figure 3. Audible noise profile

Options Evaluated

The first option evaluated was the ACSS conductor. It was the first alternative option because of its material familiarity with ACSR and its low price point in relation to other advanced conductors. No ACSS cables were able to meet the ampacity and tension requirements set forth for this case. The ACCC conductor was also considered. It was ruled out as an option because of repeated failures in lab testing, as well as the lack of redundancy of a monolithic core. The third advanced conductor option considered was the ACCR. The drawbacks to this conductor were its price and that it had materials unfamiliar to BPA crews. This conductor has tested well and was shown to be reliable where it had been installed in the past. ACCR conductors could meet the loading and amperage requirements. Ultimately, the ACCR conductor was chosen. A twin bundle of 1.1 in. (28 mm) T16 Suwanee will be used, operated at a maximum of 210°C. This results in a rating of 3600 amp.

Justification for the Selection of a Specific Advanced Conductor

Despite the high conductor price, the ability to replace the 2.5-in. (64-mm) expanded conductor with a bundle without tower modification justified its purchase. This will eventually be used in about 10 locations on the BPA system. The twin-bundle Chukar ACSR will continue to be the standard replacement when and where it works.

Installation Process

When the initial information was supplied, the installation had not taken place.